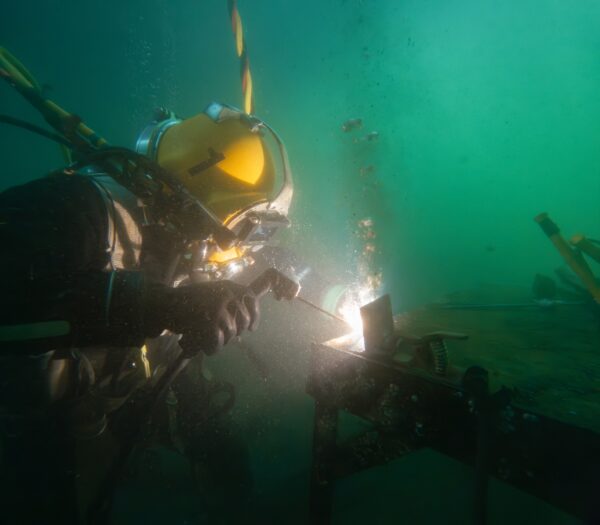

Subsea Welding

Subsea welding plays a pivotal role in the installation and maintenance of underwater infrastructure ranging from offshore oil and gas platforms and pipelines to submarine bases and marine vessels. Traditionally, it has been high-risk, logistically complex, and cost-intensive. Its inherent challenges such as pressurized environments, poor visibility, and diver safety drive the need for innovative…