Seabery Welding PRO is the solution for the welding training digitalization on the industrial sector which adapts itself to the necessities of each client.

Our exclusive service model, proprietary trademarked technology and highly qualified welding & software experts can adapt solutions to your customized needs regardless of size or complexity.

Solutions to Maximize Your Performance

Increase Efficiency and

Maximize Performance

Reduce Risks and Environmental Impact

Upskill Trained Professionals Effectively and Quickly

Maximize Quality and Reduces Cost

1. ASSESSMENT

Customer needs deep dive

Recommended solutions

ROI estimation

Viability study of potential solutions

Detailed scope of work for next phases

Investment proposal

Estimated ROI calculation

2. DEVELOPMENT

Simulation parametrization

Custom solutions development

3. IMPLEMENTATION

Solutions installation

Train-the-trainers

Training contents digitalization

4. SAAS: SOFTWARE AS A SERVICE

Dedicated post-implementation service

(maintenance & support)

Performance Monitorization

Continuous improvement

Innovation pipeline support (new joints and solutions needed)

The experience of Seabery on the industrial sector along with the technological development of Soldamatic, have enable to develop a specific solution for the training of professional welders, which uses joints and working procedures in Augmented Reality like those used in a real chain production.

Defense

Automotive

Railway

Shipbuilding

Oil&Gas

Real results

High Quality Performance

Instructor can track each exercise and welder individually.

Cost Reduction

66% cost reduction in materials and consumables.

Efficiency

Real practice time reduced by 32%

Safety

Simulated training eliminates risk of injury and teaches correct postures to increase safety.

Environmental Friendly

99% reduction of CO2 emissions

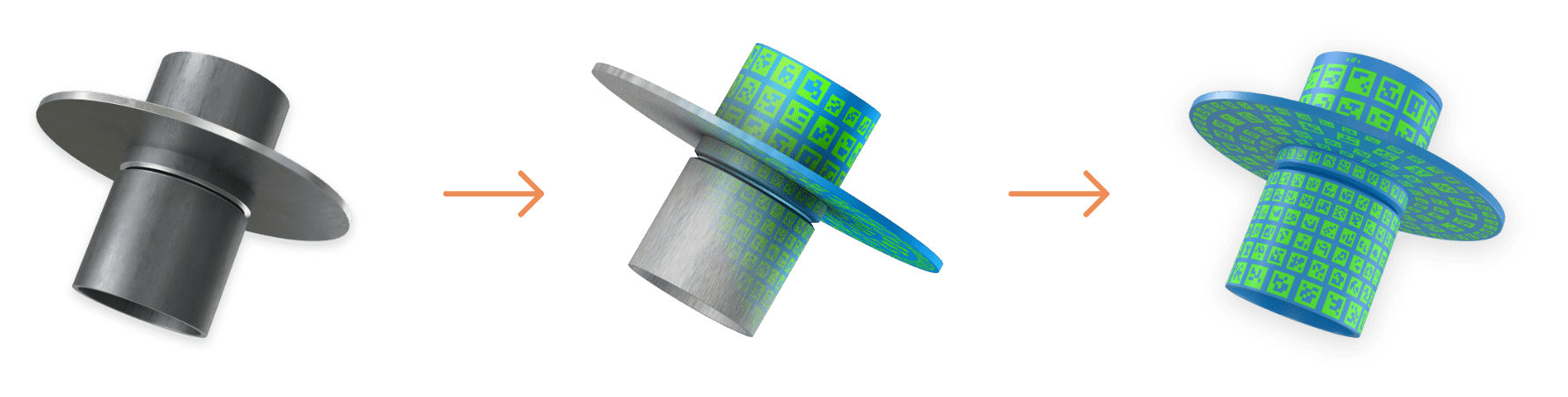

Industrial Welding Multijoints

Bring your own joints to Augmented Reality, train you welders in AR before moving on to the real joint.

CASE STUDIES

Mercedes Benz AG

Automotive Sector

The Mercedes plant in Bremen, Germany, which manufactures up to 10 different models, uses Soldamatic for training and qualification of its professional aluminum welders.

MIN 11’30”

BMW Group Werk Regensburg

Automotive Sector

Accurate, sustainable, safe training relies on “virtual welding – based on augmented reality”.

Soldamatic has been part of Regensburg’s vocational training program since 2021. Instructions and tips are displayed during the welding process; detailed analyses of the weld seam are possible afterwards. In addition to qualitative progress, the digitization project also contributes to the “green factory”: Compared to conventional learning welding, less metal scrap is produced. Electricity and material consumption are reduced. The significantly lower risk of injury is also among the positive effects. Only when sufficient basic knowledge has been acquired in the course of virtual welding do the trainees switch to the “real” welding machine.

Volkswagen

Automotive Sector

The Volkswagen site in Emden, Germany, uses Soldamatic for training professional welders. Thanks to the use of Augmented Reality, they have been able to reduce material costs and training times, as well as increase productivity

Alstom

Railway sector

The multinational Alstom, a pioneer in the digitization of the industrial sector, uses Soldamatic for training and selection of welders according to its high-quality standards. This has enabled it to reduce the cost of materials by up to 40% as well as its environmental impact.

The Cornwall College + Pendennis Shipyard

Educational Sector + Shipbuilding Sector

The Cornwall College and Pendennis Shipyard work together to develop the next generation of engineers and welders. The Cornwall College trains its students according to Pendennis requirements, preparing them for the real jobs demanded by the industry. Soldamatic plays a fundamental role in this agreement, preparing students for a real job in the shipbuilding sector.

Samsung Global Top Smart Shipyard

Shipbuilding Sector

What does transition skills training look like? Welding technology is essential in the industrial field. This site is Samsung Global Top Smart Shipyard, a large shipyard located in Korea operated by Samsung. In this Augmented Lab, risky training can be made safer, and experiential education is as good as on-the-job training.

Strategic Marine

Shipbuilding Sector

Strategic Marine is a leading shipbuilder with an international outlook and an established reputation for producing quality, high performance commercial & governmental vessels for markets across the globe. The company uses Soldamatic to train its welders in the most efficient, economical, fast and sustainable way.

John Deere

Industrial Sector

John Deere uses Soldamatic Augmented Training in Germany to train metalworking students in its welding and assembly fabrication processes.