For ten years now, we have been developing and improving Soldamatic – the first & only, most experienced Augmented Reality based solution for digital education and training of welders.

But what is Augmented Reality and how does it differ from Virtual Reality? Why are these differences of high relevance especially when it comes to the education and training of welders? Augmented Reality and welding – traditional craftsmanship meets state-of-the-art technology. How does this fit together? We answer these questions in the following article.

What is the difference between Virtual Reality and Augmented Reality?

Augmented Reality (AR) and Virtual Reality (VR) are reality technologies that either augment or replace a real environment with a simulated environment. Augmented Reality extends your environment by adding digital elements to a live view, often using one or more cameras. Virtual Reality (VR) is a purely immersive experience that completely replaces a real environment with a simulated environment.

In AR, a virtual environment is designed to coexist with the real environment, with the goal of providing additional and informative data about the real world that the user can access.

Why are these differences highly relevant especially when it comes to the education and training of welding professionals?

Welding is a practical and traditional craft. It requires experience and constant practice to learn motion sequences, master precision and acquire knowledge of the characteristics of different metals, materials, and welding processes to be welded. The ability to properly inspect weld defects is also important. To learn these skills and abilities, the AR-based solution for digital education and training of welding professionals offers various advantages:

1. Train motion sequences, learn precision and build muscle memory

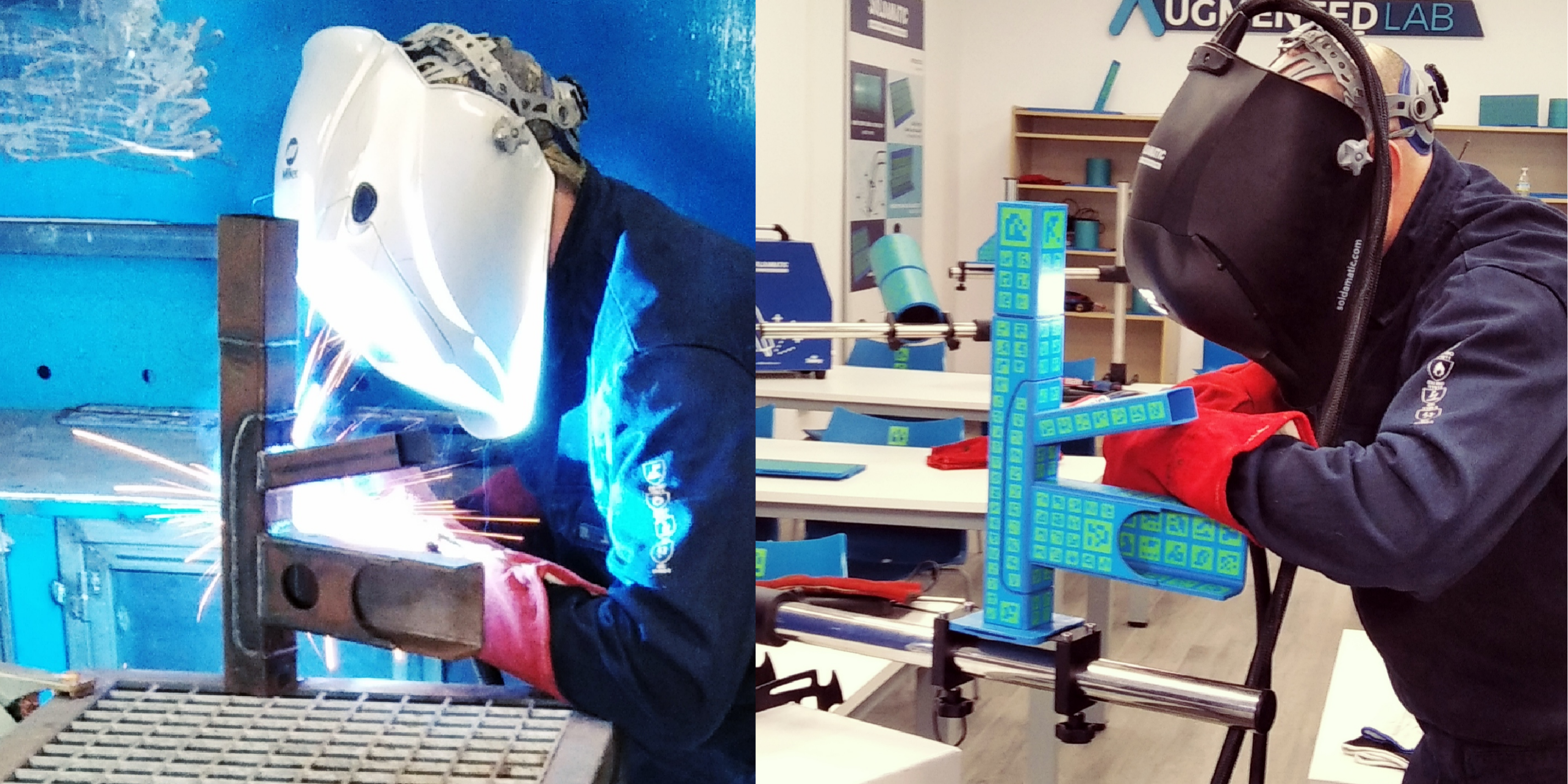

Augmented Reality training from Soldamatic has nothing to do with virtual reality simulations. In virtual reality, all components of the real world are replaced by an imaginary world. Soldamatic is equipped with various physical welding components, including a welding helmet, gloves, professional haptic welding torches, all technologically and digitally enhanced to create a highly realistic and intense welding experience. The use of this welding equipment, enables safe but realistic training, allowing users to perform even complex welding operations with completely natural movements. Over time, this also builds muscle memory and teaches proper posture for welding, resulting in a proven 56% reduction in learning time and 84% fewer accidents compared to traditional education and training methods. Soldamatic provides the opportunity to repeat and practice welding instructions repeatedly. In this way, the welders consolidate their movements and muscle memory, and learn the precision needed to guarantee reliable work as a welder in the future.

2. Knowledge of the characteristics of metals, materials, and welding processes to be welded

Soldamatic has been parameterized with Welding Procedure Sheets (WPS), in real environments, under different scenarios and including numerous positions and possible welding scenarios (e.g. by analysing macrographs, video recording of the weld puddle, welding sounds, etc.). This parameterization, in combination with the physical welding components, ensures that the characteristics of the metals to be welded accurately reflect reality and that welders can acquire knowledge of the metals, materials and welding processes to be welded in a realistic and haptic way during training with Soldamatic. Once again, the infinite number of repetitions of the exercises made possible by Soldamatic makes it possible to consolidate this knowledge.

3. Detection of weld defects

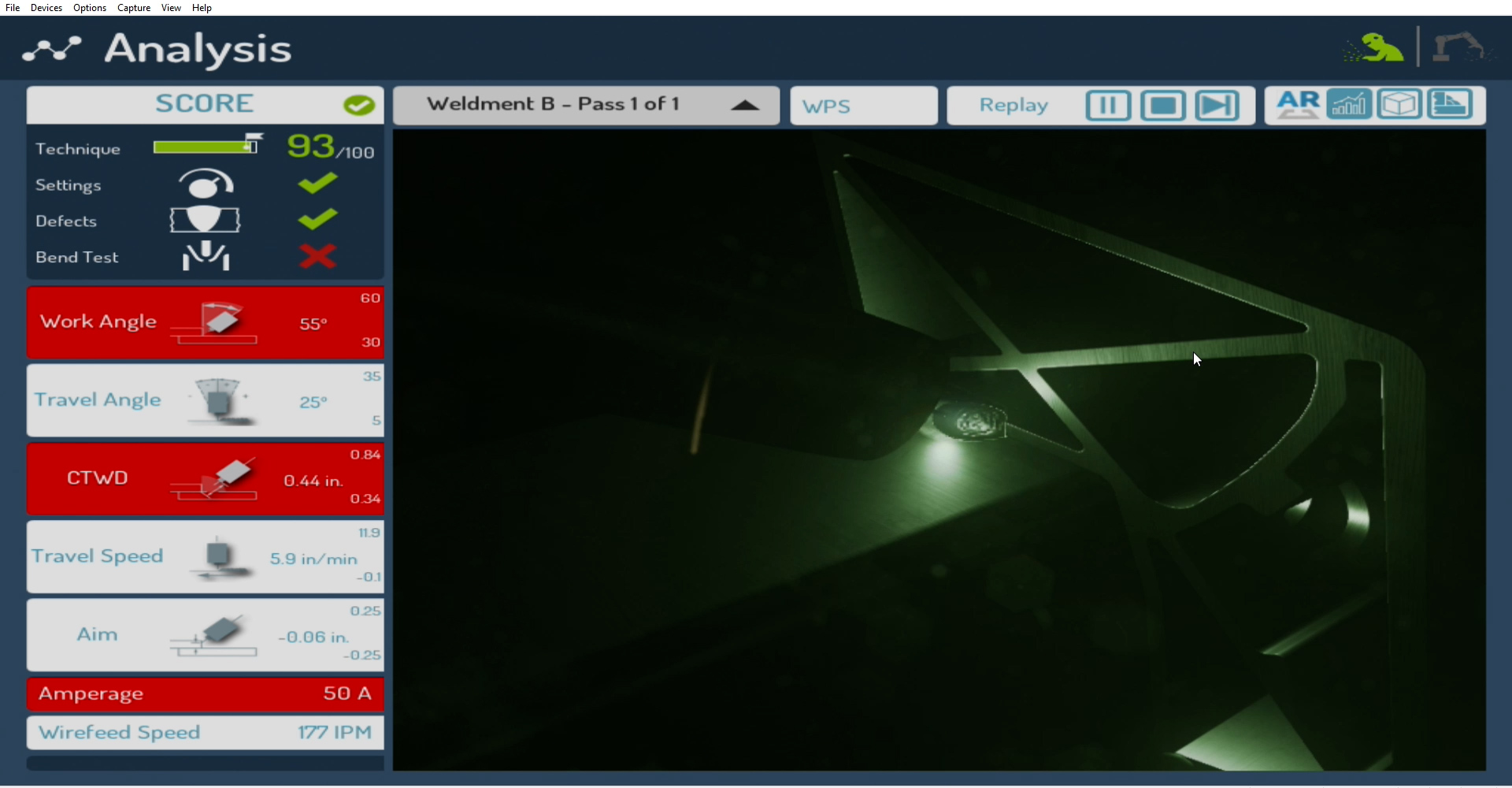

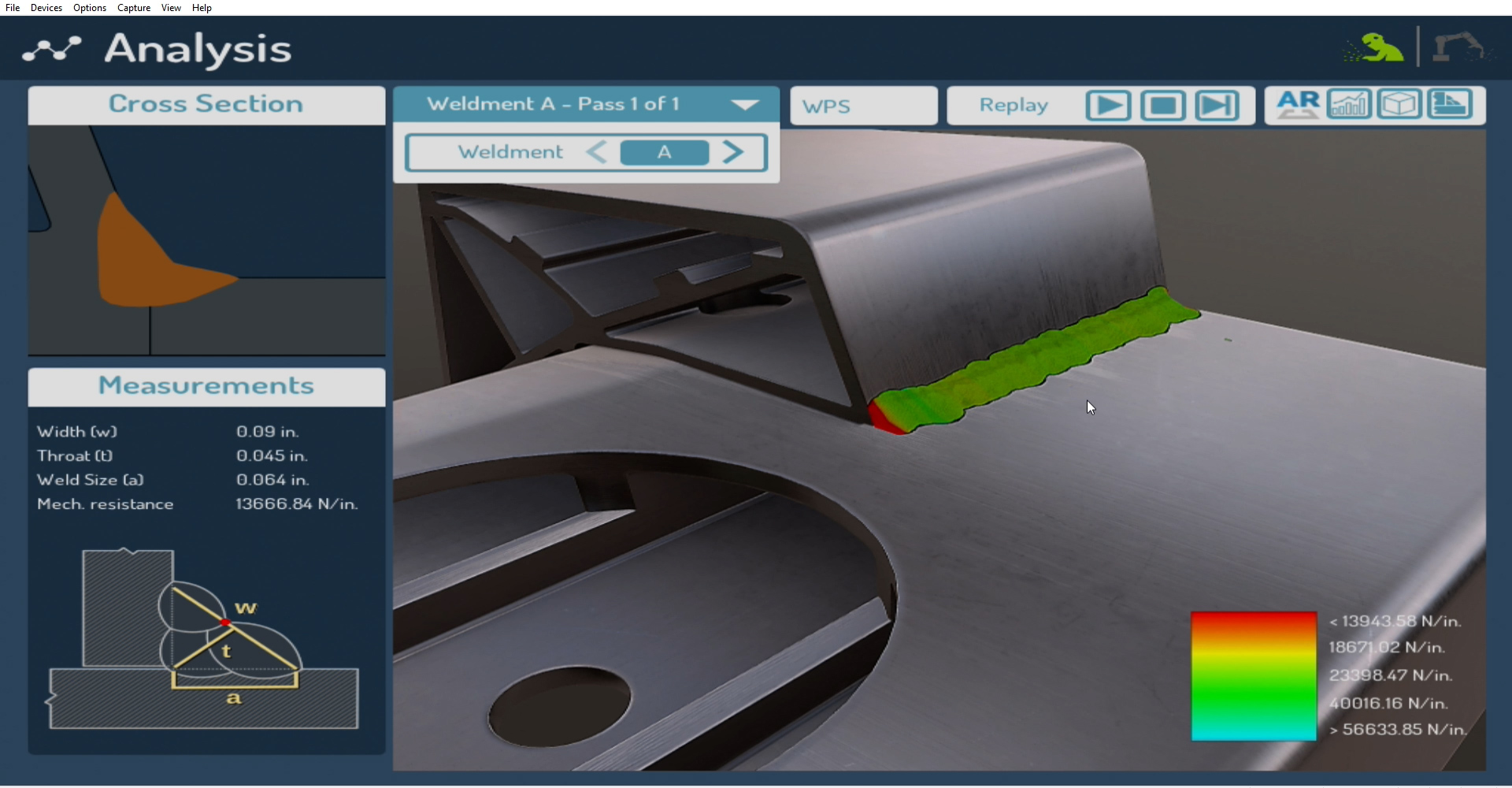

Soldamatic’s analysis tool allows trainees to record various parameters and analyse exercises – something that is not possible with traditional training and education methods for welders. Soldamatic records all parameters in real time. Thus, users know what is happening at all times during the welding process and can correct errors both during and after the practical exercise. The program continuously records the position of the hand, the welding speed and the angle of the welding torch and detects any deviation of the values from the welding instruction. On the one hand, the resulting weld can be put through its paces purely visually by taking the haptic workpiece in one’s hands and viewing the seam in detail from all sides. In contrast, the “cross-section” of the analysis module shows the technical parameters for evaluating manual welding skills and lists the measured errors of the welding exercise. At the same time, it incorporates video replays and 3D views of the training exercise to analyse the results. Through numerous repetitions and analysis of their own performance, welding professionals can gain experience with diverse materials, learn to work with foresight to identify sources of danger and avoid serious workplace accidents. This supports the sense of responsibility that is essential for a welding specialist.

Analysis module features: Mechanical Resistance and Bend Test

Analysis module features: Cross Section

Augmented reality and welding – How does that fit together?

Traditional craftsmanship meets state-of-the-art technology

Training with Soldamatic does not replace hands-on training in the welding workshop, but it perfectly complements it. It prepares welders in training and further education for practical welding and can significantly improve this through the previously mentioned various advantages that Augmented Reality provides. In addition, Augmented Methodology recommends that alternating between augmented training and training in the welding workshop can take place to constantly develop the trainees’ skills and abilities. All of this is made possible by Soldamatic with significantly lower material costs, electricity costs, in less time and in a resource-saving and sustainable way. Advantages whose relevance for companies and institutions, especially nowadays and due to the current economic, ecological, and social circumstances is constantly increasing.

Other simulated welding qualification solutions do not compare to Soldamatic’s Augmented Reality Training. Soldamatic’s Augmented Reality Training enhances the welding experience, providing the most hands-on and realistic experience.

Remember, welding is a demanding process, so Soldamatic should not be confused with a video game. Rather, it’s a digital technology that sets the standard.