Welding is a fundamental process in the industrial sector, essential for constructing and maintaining metal structures. However, it presents several risks that can compromise the safety and health of the welder if not properly managed. Understanding these risks and implementing effective preventive measures is crucial.

Common risks in welding

| Exposure to fumes and gases | Welding produces hazardous fumes and gases that can lead to respiratory issues and other health problems. Inhaling these substances without proper protection can have serious long-term effects. |

| Eye and skin injuries | The intense light from welding arcs can cause ‘arc eye’ or photokeratitis, a painful condition resulting from UV exposure. Additionally, sparks and hot metal can lead to burns. |

| Electric shock | Welders are at risk of electric shock, which can result in severe injury or fatality, especially when working in damp conditions or with faulty equipment. |

| Fire and explosions | The high temperatures and sparks generated during welding can ignite flammable materials, leading to fires or explosions if the workspace is not properly managed. |

| Physical strain | Welding often requires awkward positions and repetitive motions, contributing to musculoskeletal disorders over time. |

Preventive measures

Welding safety should not be an afterthought but an integral part of every operation. Welders and employers must adopt a comprehensive safety strategy to mitigate these risks. The following measures should be implemented.

1) Ventilation and fume extraction: Ensure adequate ventilation in the workspace and use local exhaust systems to remove hazardous fumes and gases from the welder’s breathing zone.

2) Personal Protective Equipment (PPE): Welders should wear appropriate PPE, including auto-darkening helmets, flame-resistant clothing, gloves, and safety boots, to protect against burns, eye injuries, and electric shock.

3) Regular equipment maintenance: Inspect and maintain welding equipment regularly to prevent malfunctions that could lead to accidents.

4) Fire safety protocols: Keep the workspace free from flammable materials and have fire extinguishers readily available. Welders should be trained in fire response procedures.

5) Ergonomic practices: Design workstations that promote good posture and provide ergonomic tools to reduce physical strain.

By implementing preventive measures, companies can significantly reduce workplace injuries, improve efficiency, and create a safer work environment for welders.

| Welding risks | How to prevent them |

| Exposure to fumes and gases | Ventilation and fume extraction |

| Eye and skin injuries | Personal Protective Equipment (PPE) |

| Electric shock | Regular equipment maintenance |

| Fire and explosions | Fire safety protocols |

| Physical strain | Ergonomic practices |

The role of Augmented Reality for risks prevention

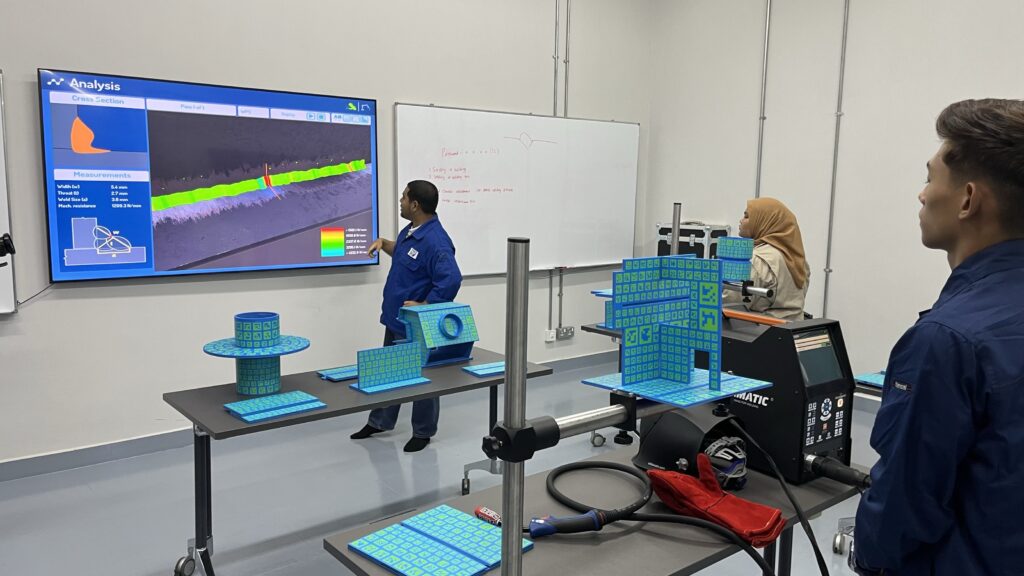

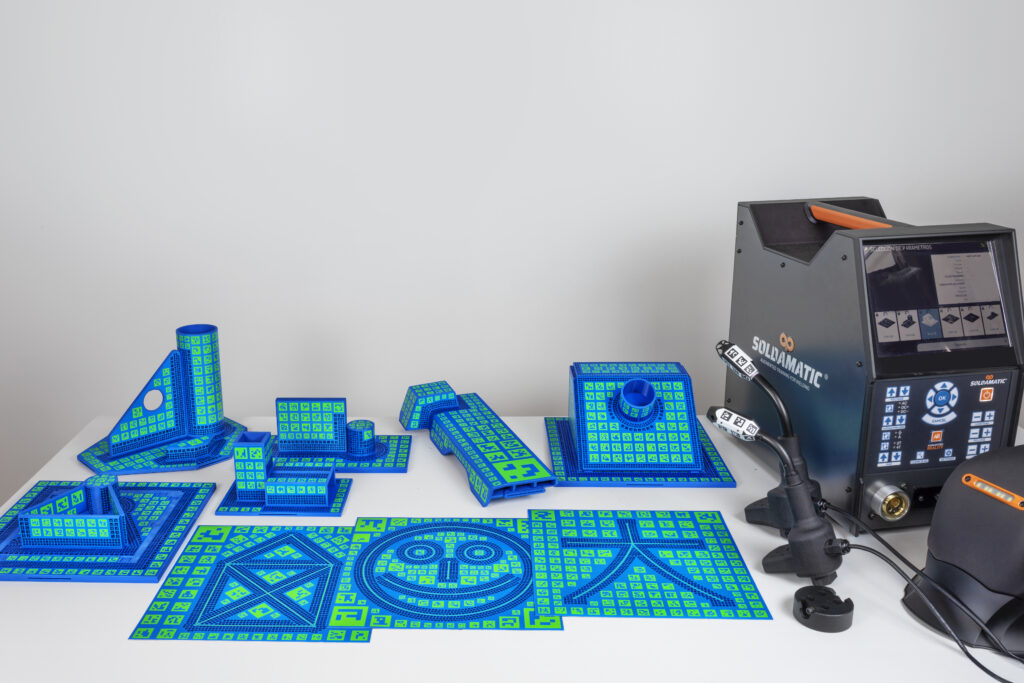

As the industrial sector continues to evolve with digitalization and automation, adopting innovative methodologies becomes imperative. Augmented Reality is transforming welding by providing immersive, risk-free environments for skill development. The combination of traditional safety practices and modern technological advancements plays a crucial role in ensuring the well-being of workers. Solutions like Seabery Welding Simulator are revolutionizing how industrial companies train and upskill their welding workforce across the globe.

One of the most significant advantages of this technology is the opportunity for risk-free hands-on experience. You can practice welding techniques in a simulation that mimics real-world conditions, without being exposed to hazards such as heat, fumes, or electrical shock. This also creates a safe space where beginners can build confidence and core skills from day one.

Another benefit is the availability of immediate feedback. Seabery Welding Simulator analyzes the user’s technique in real time, offering instant evaluations and corrections. This accelerates the learning process, helping welders to build proper habits early on and avoid repeating mistakes.

AR also enables a much broader learning experience through its ability to simulate a variety of scenarios and materials. From different joint types and welding positions to varied industrial settings, trainees can engage with realistic challenges that prepare them for the complexities of real-world welding tasks.

In addition to technical skill-building, AR plays a key role in improving safety awareness. By allowing users to visualize potential hazards within a virtual setting, the technology fosters a deeper understanding of safety procedures and personal protective equipment (PPE) usage, which are essential habits that translate directly into the workplace.

AR-based welding training is also cost-effective because AR significantly reduces the need for consumables such as wire, gas, and metal plates, which lowers operational costs and minimizes waste. For institutions and companies alike, this makes welding programs more sustainable and budget-friendly.

Finally, AR serves as a compelling way to attract new talent into the welding profession. Its interactive and resonates with younger generations, helping to make welding education more appealing and aligned with modern expectations. This is particularly valuable at a time when the industry faces a global shortage of skilled welders.

Embracing technology for a safer future

Integrating Augmented Reality into welding not only enhances skill acquisition but also significantly improves safety outcomes. In addition, embracing new technologies ensures that welders are well-equipped to meet the demands of modern industry while maintaining the highest safety standards.

Understanding the inherent risks of welding and implementing comprehensive preventive measures are essential for the well-being of welders. The advent of AR in welding offers a promising avenue to enhance safety, efficiency, and skill development, paving the way for a safer and more proficient industrial workforce.