Welding is a crucial process in various industries, from manufacturing and construction to aerospace and automotive. Its significance lies in creating strong and durable bonds between metal components, ensuring the integrity and safety of structures and products. However, the quality of welding heavily depends on the skills and knowledge of the welder. This is where welding certification comes into play – a formal recognition of a welder’s competence, skill level, and adherence to industry standards. In this article, we will delve into what welding certification entails, why it is so important, and how it benefits both welders and the industries they serve.

Understanding the Welding Certification

Welding certification is a documented verification that a welder possesses the necessary skills and knowledge to perform welding tasks to a specific set of standards. These standards often include factors such as joint configuration, welding position, and material types. Certification is usually granted by a recognized certifying body, which can be either an independent organization or an industry association.

A welding certificate serve as evidence that the certificate holder has gained a certain level of proficiency and competence in performing welding tasks according to specific standards. These certificates can be obtained through vocational schools, community colleges, trade schools, technical institutes, and even some apprenticeship programs. Some common topics covered in welding certificate programs include:

- Welding processes: Different welding techniques such as MIG (Metal Inert Gas), TIG (Tungsten Inert Gas), stick welding, and more.

- Safety procedures: Knowledge of safety protocols to prevent accidents and protect oneself and others from hazards related to welding.

- Materials and metallurgy: Understanding the properties of various metals and how they respond to welding.

- Blueprint reading: Interpreting engineering drawings and plans to accurately perform welding tasks.

- Welding equipment operation: Learning how to set up and use welding machines, torches, electrodes, filler materials, etc.

- Welding joint types: Understanding different joint designs and their applications.

- Quality control and inspection: Techniques to assess the quality of welds and ensure they meet industry standards.

Certification typically involves a combination of theoretical knowledge and practical skills evaluation. The welder must demonstrate their ability to create sound welds that meet quality and safety standards. Welding tests may include different welding techniques, materials, and positions, ensuring that the welder is versatile and capable of handling various scenarios. The specific certification obtained can depend on factors like the type of welding processes learned and the industry standards being followed. Common welding certifications include those from organizations like the American Welding Society (AWS) and other regional or national bodies.

Importance of the Welding Certification

- Quality Assurance: Welding certification ensures that welders meet or exceed industry standards, resulting in consistent and high-quality welds. This is crucial to maintain the structural integrity and safety of the finished products or structures.

- Safety: Welding involves working with high temperatures, electrical equipment, and potentially hazardous materials. Certified welders have been trained in safety procedures and are aware of potential risks, minimizing accidents and injuries.

- Compliance: Many industries have stringent regulations and codes that govern welding processes. Certified welders are well-versed in these regulations and can ensure compliance, avoiding costly penalties and legal issues.

- Industry Credibility: Companies seeking skilled welders often prioritize candidates with welding certifications. Holding a certification demonstrates a commitment to the profession and a dedication to maintaining high standards.

- Career Advancement: Welders with certifications have greater opportunities for career advancement. They can take on more challenging projects, supervisory roles, or even become welding inspectors or educators.

- Versatility: Welding certifications often cover a range of welding techniques, materials, and positions. This versatility allows certified welders to adapt to various project requirements, making them more valuable assets to employers.

- Global Recognition: Welding certifications are often recognized internationally. This is especially valuable in industries where products and components are manufactured and used across borders.

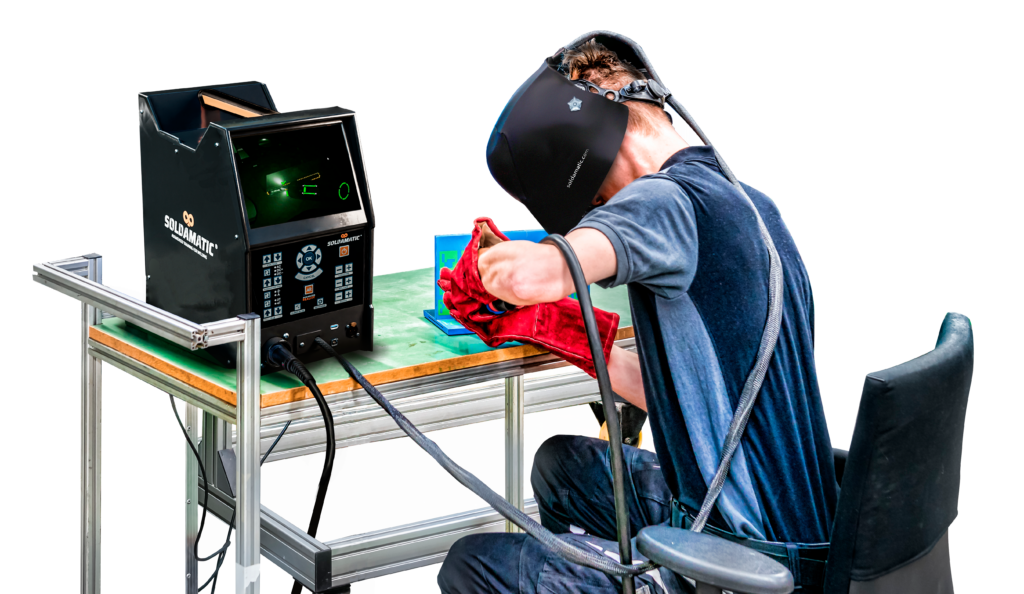

How to be ready for the welding certification: Soldamatic, the welding simulator

Soldamatic empowers students to fully immerse themselves in simulation environments, enabling them to practice without any constraints, risks, or financial burdens. Through this process, students can progressively acquire the essential skills and competencies required for real-world settings. Additionally, with the analysis module they can assess their performance after each practice session and look for the areas where they need to focus and improve.

Seabery is dedicated to engage with the latest generations and partner with the state-of-the-art technology. We achieve this by crafting training programs that cultivate a highly proficient workforce capable of addressing the specific needs of the industrial sector, particularly in welding.

There are many courses currently available for our welding training solution for teachers who wants to use the most advanced welding simulator, which have been developed along with relevant organizations mentioned in this article (DVS, AWS, CESOL…).

These courses have been created as a result of this partnership to prepare the trainees and achieve the Welding Certification. The combination of several practices, and those courses together with the e-learning software is what we call “Augmented Training”. Ask in your educational center if they have already implemented the most powerful welding training solution.

As a conclusion: The Last Word

Welding certification is a crucial aspect of the welding profession, ensuring that welders possess the necessary skills, knowledge, and commitment to producing high-quality and safe welds. It offers a range of benefits, from enhancing career opportunities and industry credibility to promoting safety and compliance. Soldamatic is the perfect solution for individuals pursuing a career in welding and industries that rely on welded structures and products, because the welding certification is not just a piece of paper – it is a testament to the dedication to excellence and professionalism in a critical field.