is an all-in-one Welding Upskilling Program including simulation, optimized WPS used on digital twins, industry-specific content and best-in-class services.

Welding Upskilling Program

FASTER

Increase Arc-Time through state-of-the-art simulation.

Welders reach proficiency up to 33%* faster.

Speed up learning cycles, no setup, no cleanup.

SMARTER

Reduce raw material, energy, and consumables usage up to 66%*.

Evaluate candidates fast and objectively to boost your hiring.

*Real results from customer case study.

BETTER

Reduce the quality issues.

Guarantee delivery time.

Safe & risk free.

TRAIN LIKE YOU PRODUCE

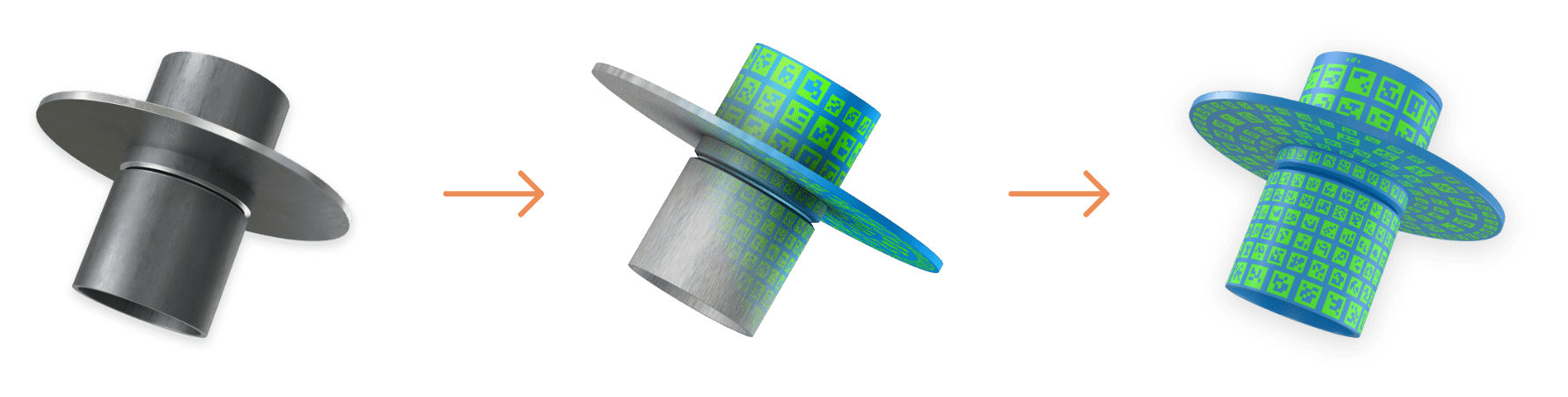

1. WPS OPTIMIZATION

We fine-tune manual skills using your PQRs, WPSs, and power source models.

2. DIGITAL TWINS PRODUCTION

Practice on coupons that replicate real parts and positions.

Build cause-effect understanding of technique.

3. ANALYSIS MODULE

Track progress with measurable KPIs.

Focus on areas of improvements.

APPLICATIONS FOR MANY SECTORS

Defense

Automotive

Railway

Shipbuilding

Oil&Gas

Back-to-back Service

Setup & Training

Lean setup implementation together with an integral E2E training to all stakeholders.

“Ad Hoc” Training program

Industry specific content & practices based on real customer needs designed to progressively acquire the manual skills.

Support

Direct Line with our Service team to guarantee up-time.

Do not get obsolete

Early access to state-of-the-art welding simulation.

SEABERY WELDING SIMULATOR VS REALITY

Thanks to its HyperReal-Sim™ simulation system, users can practise with digitally enhanced real equipment, faithfully replicating workshop conditions without risk or material consumption. The system provides real-time feedback and detailed performance analysis, facilitating the acquisition of skills in various welding positions and processes.

In addition, its compact and portable design makes it ideal for training centres and industrial sectors looking to improve efficiency and quality in welder training.

Industrial Welding Multijoints

Bring your own joints to Augmented Reality, train you welders in AR before moving on to the real joint.