The Augmented Reality (AR) market has experienced exponential growth in recent years, fueled by technological advancements, increased adoption across diverse industries, and the rising demand for immersive experiences.

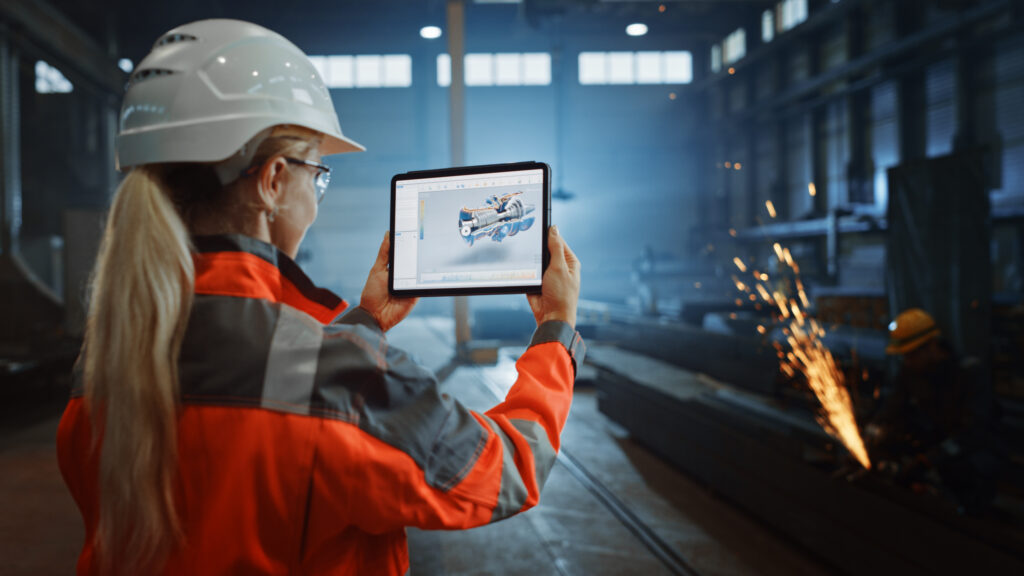

Augmented Reality is revolutionizing how companies train employees, streamline operations, and interact with customers. AR technology integrates real-time data and digital elements with the physical world. As AR technology continues to evolve, its potential applications and benefits will only grow, opening new possibilities for innovation and engagement. In this article you will discover seven examples of companies that are successfully integrating AR into their business.

But first, how does Augmented Reality work?

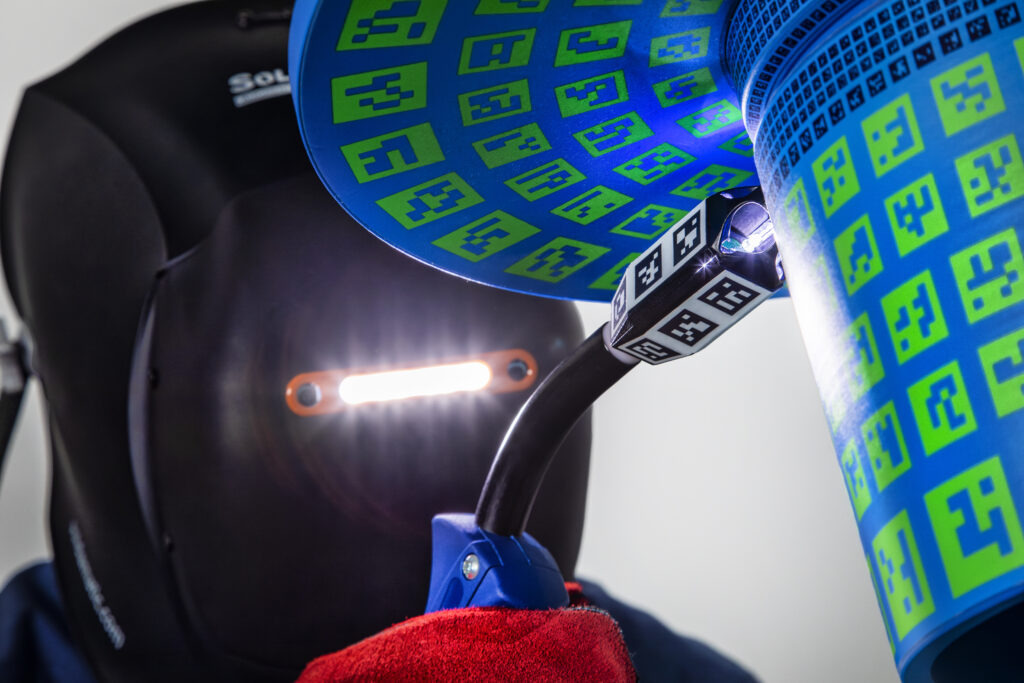

AR technology integrates real-time data and digital elements with the physical world. It uses sensors, cameras, and algorithms to detect and interpret the physical environment.

Overview of the process: step-by-step

- Detection and Tracking. AR devices use sensors and cameras to capture the real-world environment. They identify and track the position and orientation of objects in real-time.

- Processing and Analysis. The captured data is processed using sophisticated algorithms to understand the spatial relationships and context of the physical objects.

- Overlay and Integration. Digital content is then overlaid onto the real world. This content is precisely aligned with the physical environment to create a seamless and immersive experience.

Companies applying Augmented Reality

Caterpillar

Caterpillar integrates AR into its equipment maintenance and operator training programs. Technicians use AR glasses to receive step-by-step guidance and diagnostics while performing maintenance tasks on heavy machinery. Additionally, AR is used to train new operators by providing immersive simulations of complex operations.

LEGO

LEGO’s AR Studio app allows children and enthusiasts to see their LEGO creations come to life through augmented reality. Users can build virtual LEGO sets and interact with them in a real-world environment.

Lockheed Martin

Lockheed Martin, a major aerospace and defense contractor, utilizes AR to enhance the assembly process of spacecraft and aircraft. AR headsets provide workers with precise overlays of assembly instructions and component placements.

Bosch

This brand employs AR in its industrial solutions to aid in the repair of complex machinery. AR applications provide technicians with detailed, step-by-step instructions and 3D visualizations overlaid on the actual equipment.

Niantic

Niantic is a leading developer of Augmented Reality experiences, known for products like Pokémon GO, an AR-based mobile game. Niantic’s platform provides location-based AR experiences, multiplayer gaming, and social features that create immersive and interactive gameplay. The company pioneers’ innovations such as real-world events, augmented reality storytelling, and strategic AR technology partnerships, delivering memorable gaming experiences to millions of players globally.

General Electric (GE)

GE uses AR to streamline repair operations in its various industrial sectors, such as healthcare. Physicians can simultaneously interact with virtual monitors, view holographic 3D anatomy, and collaborate remotely with colleagues worldwide. This is possible by leveraging GE Healthcare’s superior imaging capabilities and MediView’s expertise in real-time augmented reality visualization and navigation.

ExxonMobil

ExxonMobil uses simulation to improve safety and efficiency in its oil and gas operations. This technology provides field workers interactive maps, and procedural overlays during exploration and drilling activities. This enhances situational awareness and improves decision-making in hazardous environments. This brand has also developed together with Groove Jones an innovative AR App highlighting carbon capture storage’s ability to eliminate 90% of industrial CO2 emissions.

|

Benefits of applying Augmented Reality |

|

Increases safety. |

|

Minimizes fumes and CO2 emissions. |

|

Improves skills and reduces the learning curve. |

|

Ensures high accuracy and reduces the risk of errors. |

|

Cost efficiency. |

|

Enhances overall productivity. |

Get to know Seabery’s Technology

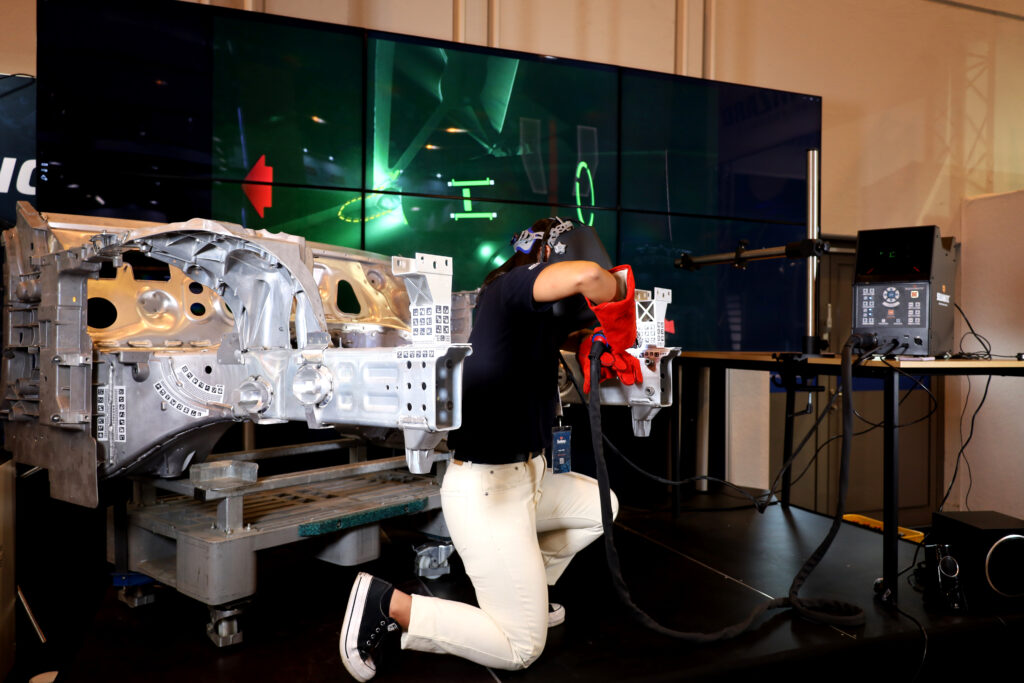

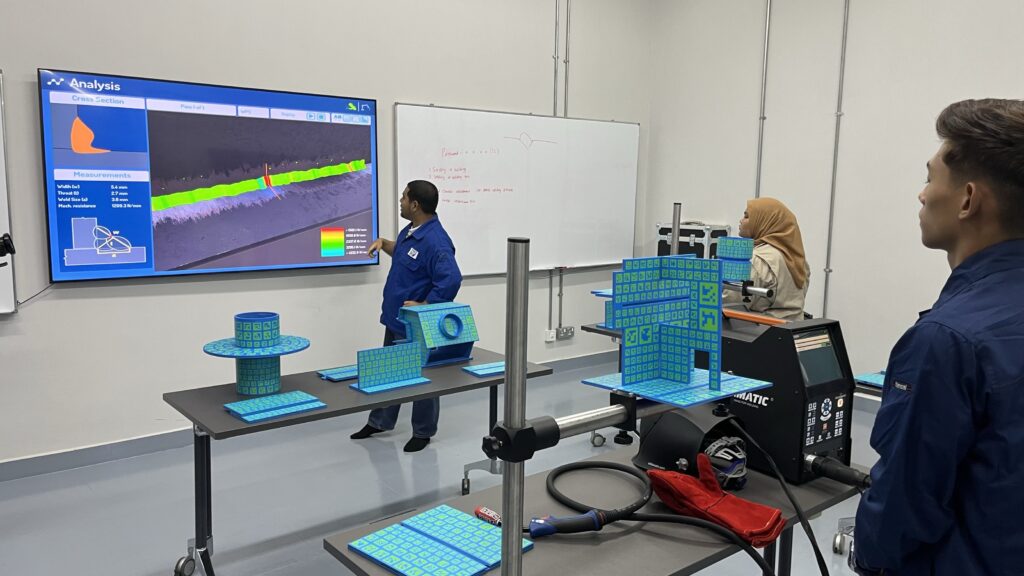

Simulation-based learning offers numerous benefits in welding, such as risk-free hands-on experience and immediate feedback, allowing trainees to learn safely and efficiently. Augmented Reality provides a variety of materials and endless combinations to practice. This green technology also promotes sustainability while ensuring accessibility for all learners. Additionally, it enhances efficiency and reduces costs, making education more effective and affordable

The Augmented Training fosters intensive, dynamic, and flexible practice, allowing the instructor to efficiently manage multiple welders of varying levels, learning paces, and locations. Soldamatic e-learning application facilitates course management and development, enabling the instructor to create content, manage courses, and monitor their progress. This welding solution also supports real-time interaction between the instructor and the trainees.

With this welding simulator you can train the next generation of welders. Analyze the technique parameters, adjustments, and defects right after the exercise. Although real-world practice remains essential: Trainees can transition to real environments once they have developed the necessary skills and abilities practicing with Soldamatic.

The Power of Augmented Reality in Industry

Whether it is through interactive learning, personalized shopping, advanced training, improved customer support, or innovative marketing, AR is transforming how businesses streamline their operations and connect with their customers.

Simulation-based learning is a highly effective approach for welding as well, enabling the workforce to prepare for real-world challenges by enhancing their knowledge, skills, and aptitudes through hands-on experience. Seabery’s Augmented Methodology is designed to enhance this learning process. Seabery: Creating immersive learning that unlocks increasingly viable skills for the future workforce.