In the drive toward industrial digitalization and automation, welding remains a field where hands-on skill, material science, and technology converge. Among different metals, aluminum presents a unique set of difficulties that require special attention. In this article we explore the main challenges of aluminum welding in industrial settings and practical tips to overcome them.

Aluminum welding: key challenges

Welding aluminum is substantially more demanding than welding steel or other ferrous alloys. Some of the core challenges include:

Oxide layer

Aluminum forms a tenacious oxide (Al₂O₃) layer almost immediately upon exposure to air. This oxide has a much higher melting point than the base metal, so if not removed or disrupted, it interferes with bonding and leads to poor fusion, porosity, or inclusion defects.

Also, aluminum is sensitive to contamination (for example: oil, grease, moisture, varnish). Even trace contaminants can produce blowholes, spatter, or weak welds.

High thermal conductivity

Aluminum has a much higher thermal conductivity than steel, meaning heat is rapidly wicked away from the weld zone. At the same time, its melting point is relatively low. The combination results in a narrow heat input window: if you use too much heat, you risk burn-through or warping; too little, and you have incomplete fusion.

Softness

Because aluminum is relatively soft and ductile, it deforms easily under heat. Warpage, distortion, residual stresses, and shrinkage are common issues, particularly for thin sections or large parts. This necessitates careful fixturing, clamping, and heat management.

Gas entrapment

Hydrogen is the main culprit of porosity in aluminum welds. Since aluminum absorbs hydrogen more readily and releases it less easily, entrapped gas leads to porosity defects. Moisture in shielding gases or on surfaces exacerbates the issue.

Incomplete fusion

A frequent problem is poor wetting, such as the liquid weld metal not spreading properly; or lack of fusion to the base metal or previous passes is a frequent problem, especially when travel speeds are high, or the torch manipulation is improper. In multi-pass welds, ensuring good fusion between passes is critical.

Solidification issues

Aluminum alloys may be more susceptible to crack formation (hot cracks, solidification cracks) especially when alloying elements or impurities are present. Maintaining correct alloy selection, filler compatibility, and process control is crucial.

Equipment

Some welding processes require more stringent control over current, waveform, and gas mixtures. Equipment stability is more critical, and parameter windows are tighter.

|

Aluminum welding challenges |

|

Contamination |

|

High thermal conductivity |

|

Low melting point margin |

|

Distorsion |

|

Porosity |

|

Incomplete fusion |

|

Cracking |

|

Process compatibility |

Tips and best practices for aluminum welding

Given the above challenges, here are proven tips and methodology pointers to improve the outcome:

Surface preparation and cleaning

- Remove any oxide via mechanical means (wire brushing with stainless-steel brush, grinding, milling) just before welding.

- Degrease and clean parts thoroughly: use solvents and then dry in warm air or bake-out if possible.

- Store parts in desiccated conditions to avoid moisture absorption.

Preheat and temperature control

- Use moderate preheat (if allowable) to reduce the temperature gradient and slow heat dissipation, especially in thicker sections.

- Control interpass temperatures carefully to avoid overheating or excessive cooling.

Welding process and parameter selection

- Pulsed GMAW is often preferred for aluminum because the pulsed waveform helps manage heat input, improves wetting, and reduces porosity.

- For GTAW, alternating current (AC) modes help clean oxides and provide stable arcs.

- Use higher travel speeds, correct torch angles (usually push technique), and short arc lengths to concentrate heat and reduce distortion.

Shielding gas and flow

- Use high-purity argon or argon-helium mixes (depending on thickness) with proper flow rates and shielding coverage to prevent atmospheric contamination.

- Ensure gas delivery systems are clean, dry, free from leaks, and use proper gas diffusers and nozzles.

Filler material and compatibility

- Match filler alloy to base material (for example using 4043, 5356, or others depending on the base aluminum alloy).

- Maintain correct wire stick-out, proper feeding, and avoid abrupt changes in weld direction or wire feed.

Multi-pass strategy and backstep technique

- When doing multi-pass welds, ensure that each pass fuses to the previous pass and sidewalls.

- Overlap correctly and perhaps use a “backstep” technique (welding short segments in reverse direction) to help manage heat input and shrinkage.

Fixturing and restraint

- Use strong clamping, fixtures, and tabs to control distortion.

- Consider heat sinking (anchoring to heavy blocks) for thin parts to reduce movement.

- Weld in a balanced sequence to reduce overall warpage (for example: progressive symmetrical welding, skip welding).

Post-weld treatments and skills development

- Stress relief (if allowed by material) or bead peening may mitigate residual stresses.

- Inspect for porosity, cracks, and fusion defects via non-destructive evaluation (NDE) techniques such as dye penetrant, ultrasonic, or x-ray.

- Aluminum welding demands consistent torch control, patience, and attention to detail. Hands-on training combined with feedback loops (for example: weld visualization) helps shorten the learning curve.

Role of augmented reality in aluminum welding instruction

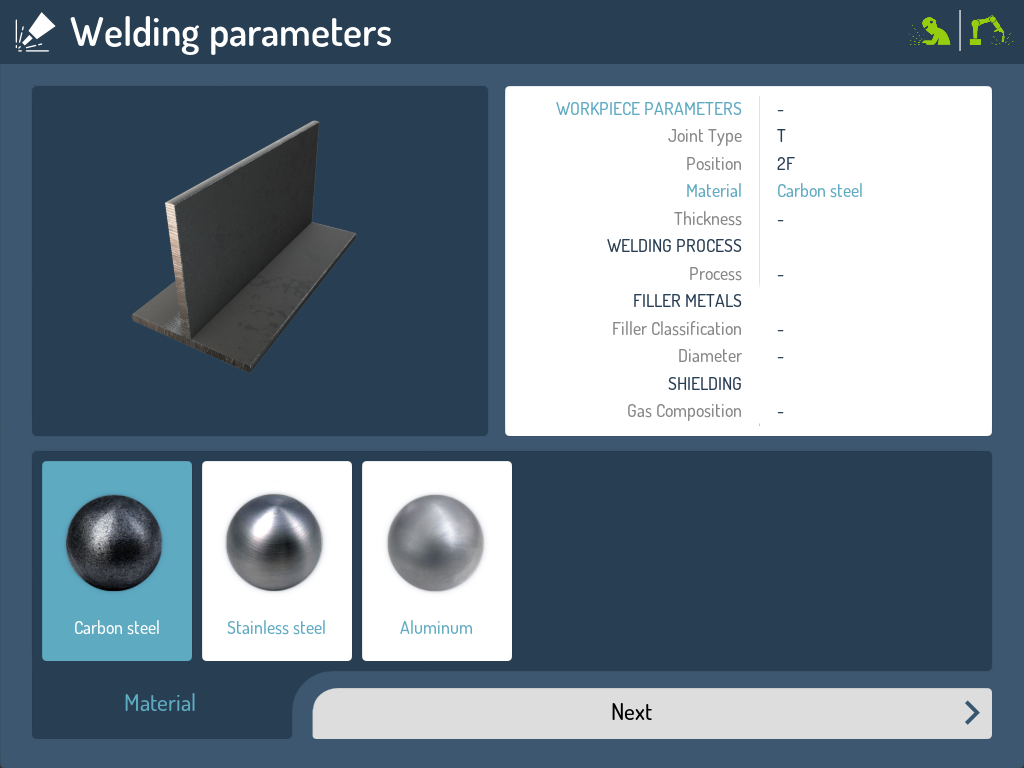

As industries push toward digitalization and automation, modern training methodologies are transforming how welders develop their skills. Among these, augmented reality (AR) welding simulators stand out as a bridge between theory and applied skill.

Seabery Welding Simulator provides real-time feedback on parameters such as arc length, torch angle, travel speed, weld bead geometry, etc., allowing users to correct techniques before applying them on real material. It can be deployed in workshop labs or distributed training environments, enabling mass instruction without requiring large amounts of physical welding workpieces and gases.

This welding solution also supports multiple materials, including aluminum, enabling users to practice aluminum-specific challenges without spending real consumables.

Multi-sensor interfaces and cameras are being used to improve accuracy and fidelity in simulated arc welding instruction, improving the learning curve. The HyperReal SIMTM engine strives to mimic real weld pool behavior, torch feedback, and defect formation. This realism helps trainees transfer virtual skills to real-world aluminum welds more effectively.

For industrial settings preparing for automation and robotics, AR-based simulation is part of workforce upskilling and bridging the gap between manual skill and automated welding systems. By embracing digitalization, Seabery’s solution helps industrial training centers and companies stay ahead as automation becomes more pervasive in welding systems.

Thus, an effective methodology in modern welding training is to combine traditional hands-on practice with augmented, digital training as a reinforcement and preparatory tool.

|

Seabery’s solution and its value for Aluminum Welding |

|

Material coverage |

|

Cost reduction |

|

Scalabe, effective, flexible training |

|

Focus on realistic experience |

|

Alignment with industry trends |

Mastering aluminum welding in a digital age

Aluminum welding poses serious challenges, such as oxide films, heat management, porosity, fusion issues, and distortion all demand care, technique, and patience. But by applying robust methodology these obstacles can be managed.

In today’s industrial environment, supplementing manual training with augmented reality is becoming a best practice. It aligns with the principles of automation and digitalization, providing controlled environments, feedback loops, and efficient skill buildup.

Seabery’s solution exemplifies how a state-of-the-art AR welding simulator can support aluminum welding training, help organizations scale their training programs more efficiently, and contribute to building a more capable, digital-ready workforce.