As welding techniques become more sophisticated, training methods need to keep pace. One innovative approach that has gained traction in recent years is the use of welding simulators. These devices are not only improving training efficiency but also significantly enhancing knowledge retention among welding trainees.

The challenges of traditional welding training

Traditional welding training often involves live demonstrations, classroom instruction, and hands-on practice in welding booths. While these methods are effective, they have several limitations:

- Safety risks: Novice welders are at risk of burns, electric shock, and other hazards during the early stages of their training.

- Resource-intensive: Traditional training requires a constant supply of metal, gas, and electricity, which adds up in cost.

- Immediate feedback is limited: In traditional training, trainees receive feedback after completing a weld, rather than in real time, which can slow the learning process.

How simulators enhance knowledge retention

Simulation is driving a new era of education, allowing learners to practice in controlled, engaging, and effective environments that foster long-term retention and skill acquisition.

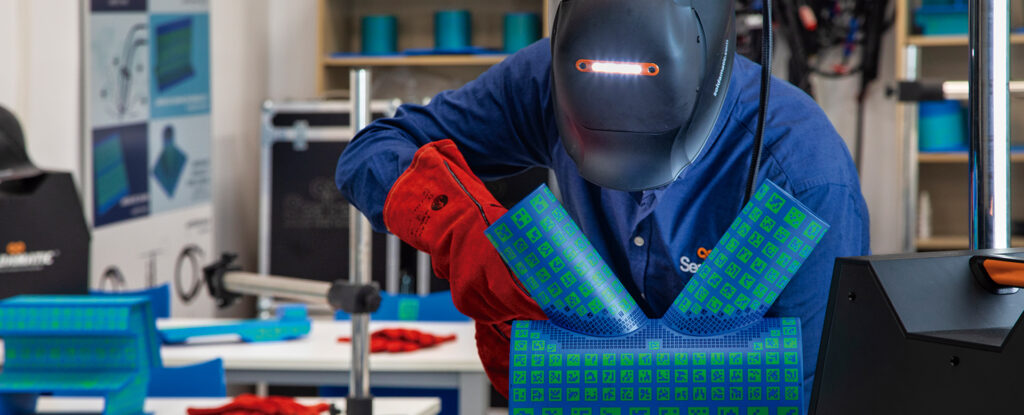

The use of simulators has a profound effect on the retention of welding skills, ensuring that knowledge gained during training remains with the student long after the course is completed. Welding simulators use virtual reality (VR) or augmented reality (AR) to recreate real-world welding conditions.

|

Benefits of training with simulation |

|

1) Enhanced memory through repetition |

|

2) Active learning and immersion |

|

3) Real-world application without real-world pressure |

|

4) Immediate feedback and correction |

|

5) Safe and cost-effective training |

The importance of a Learning Management System (LMS)

Welding training requires very personalized and individualized attention. Instructors need to spend a lot of time with each student to ensure that everyone progresses at their own pace and refines their technique.

Applications such as Soldamatic E-Learning allow instructors to centralize all this information in one place, visualizing the completed practices and even replaying them. It also generates individualized performance graphs, promoting healthy competition among students.

Moreover, these tools enable the creation of custom courses, combining theory, practical exercises, and tests. This comprehensive approach integrates multiple aspects of the learning process, ensuring students not only understand the theoretical components but can also apply them practically.

Additionally, with the e-learning platform, instructors can remotely monitor student progress, analyze performance, and provide tailored feedback. This personalized approach ensures that each trainee focuses on their specific weaknesses, resulting in faster and more effective skill acquisition.

Feedback as a path to improvement

In a real workshop, feedback is often received after the fact because the instructor cannot be with every student while they are performing the practical work.

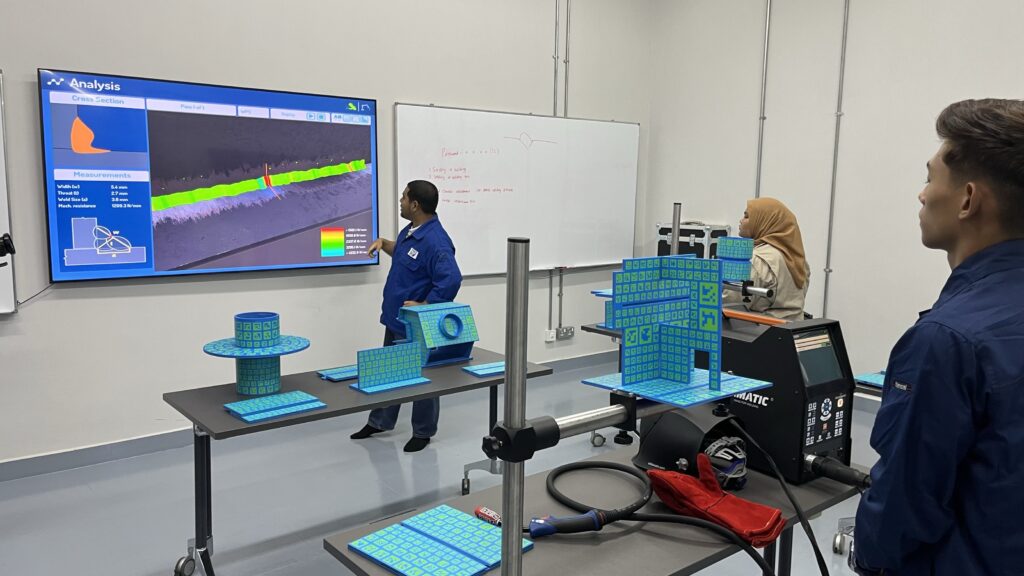

Seabery offers an AR-based solution that blends virtual and real elements. This welding solution leverages AR to create a hyper-realistic training environment, making an effective tool in enhancing retention through immersive learning experiences. The system is designed to provide trainees with real-time feedback. This feature called “analysis module” allows trainees to immediately correct mistakes, reinforcing learning in the moment. This immediate feedback mechanism has been shown to significantly improve knowledge retention compared to traditional methods, where feedback is often delayed.

The analysis module not only allows the practice to be replayed but also provides comprehensive feedback on all parameters that affect the welding process (speed, angle, etc.) at each moment during the exercise. This enables the student to focus on specific parameters where they can still such as torch speed, work angle, travel angle, and electrode distance.

The advanced analysis module complements this information with a bend test and mechanical resistance data of the weld bead at each point of the welding process. The simulator helps students understand how each factor contributes to the quality of their welds. Instructors can replay and analyze the practice sessions, which adds depth to feedback.

Improving safety and minimizing material waste

Augmented reality allows repetitive practice in a controlled environment, which is key to mastering complex welding techniques. This hands-on, repetitive exposure to different welding practices improves muscle memory and cognitive understanding, which are crucial for long-term retention of skills.

Soldamatic also offers a risk-free environment where trainees can make mistakes without safety concerns. Since traditional welding involves handling dangerous equipment and materials, this stress-free atmosphere helps learners focus more on technique and skills rather than safety risks, which enhances their ability to retain knowledge. Furthermore, it reduces material waste by 68% and lower accident rates by 84%, providing a more sustainable training environment.

The advanced analysis module complements this information with a bend test and mechanical resistance data of the weld bead at each point of the welding process. The simulator helps students understand how each factor contributes to the quality of their welds. Instructors can replay and analyze the practice sessions, which adds depth to feedback.

The future of welder education: combining traditional and simulated training

Welding simulators are transforming how welders are trained, making the process safer and more conducive to long-term knowledge retention. We can expect to see a new generation of highly skilled welders entering the workforce, prepared to undertake complex challenges with confidence.

By integrating traditional and simulated learning methods such as Soldamatic, educators can offer a comprehensive and engaging training experience that ensures trainees not only learn welding but retain the knowledge and skills they need to succeed.

Soldamatic has been widely adopted in vocational schools, industrial companies and training centers around the world. This simulator improves knowledge retention and reduce training time by up to 56%, based on research conducted with users.