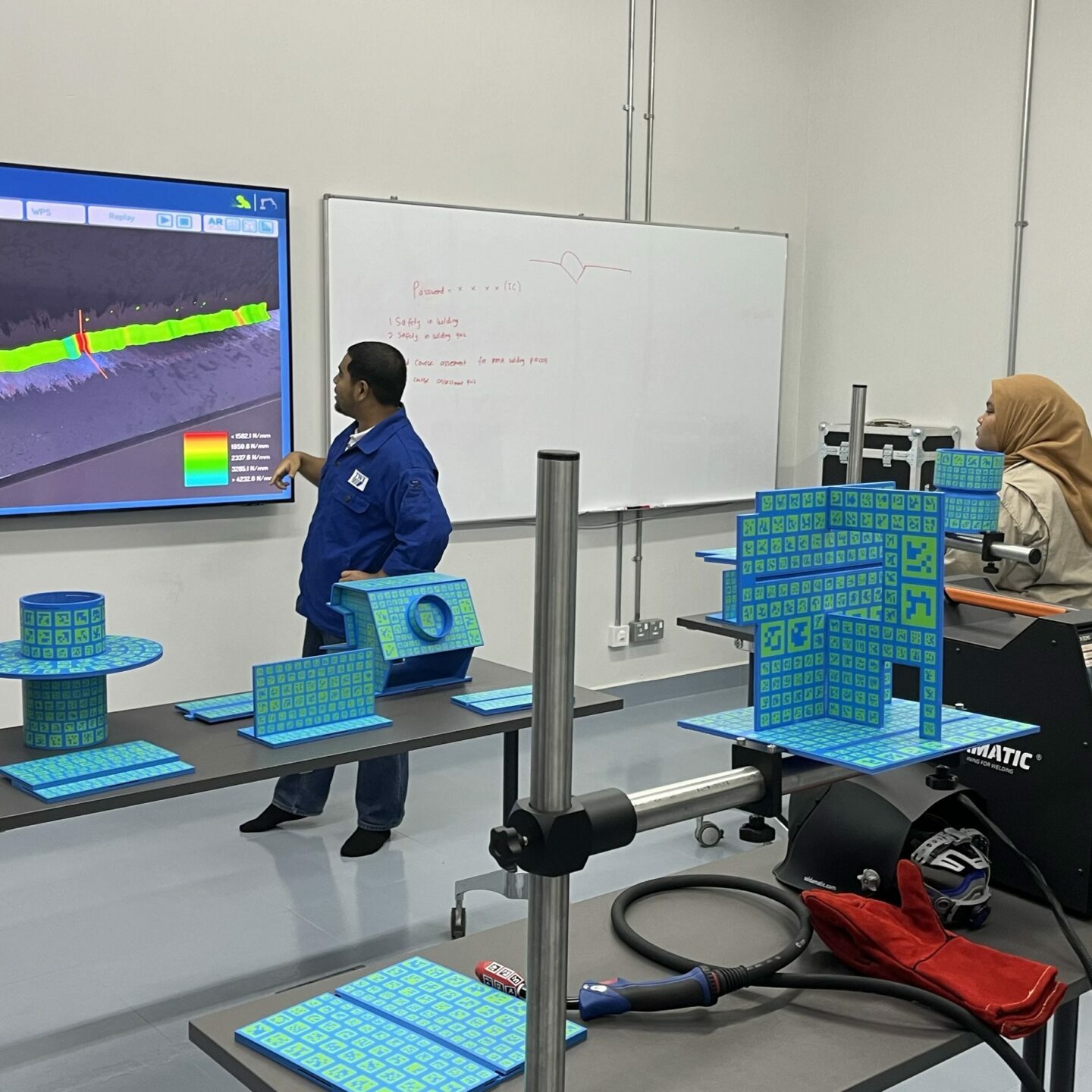

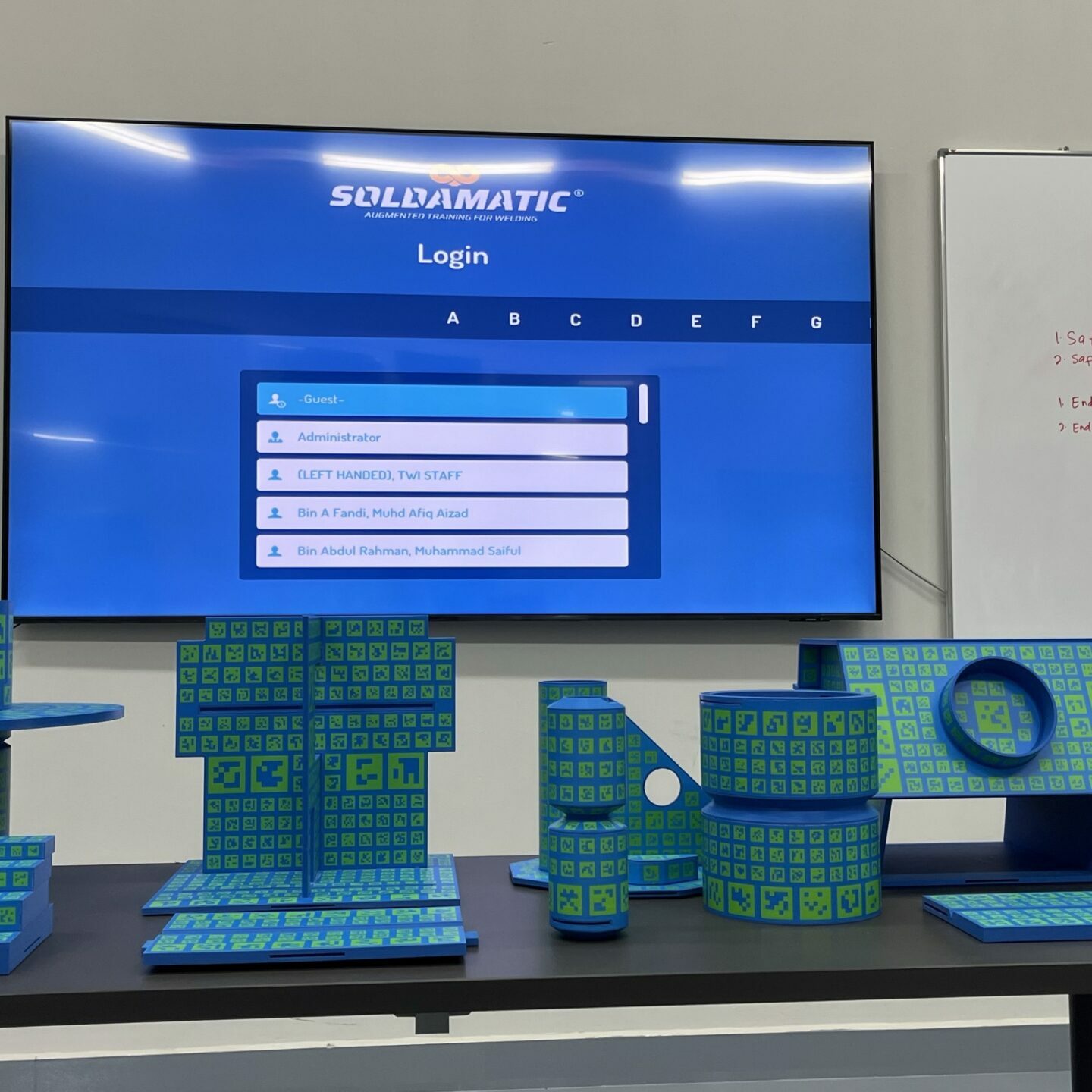

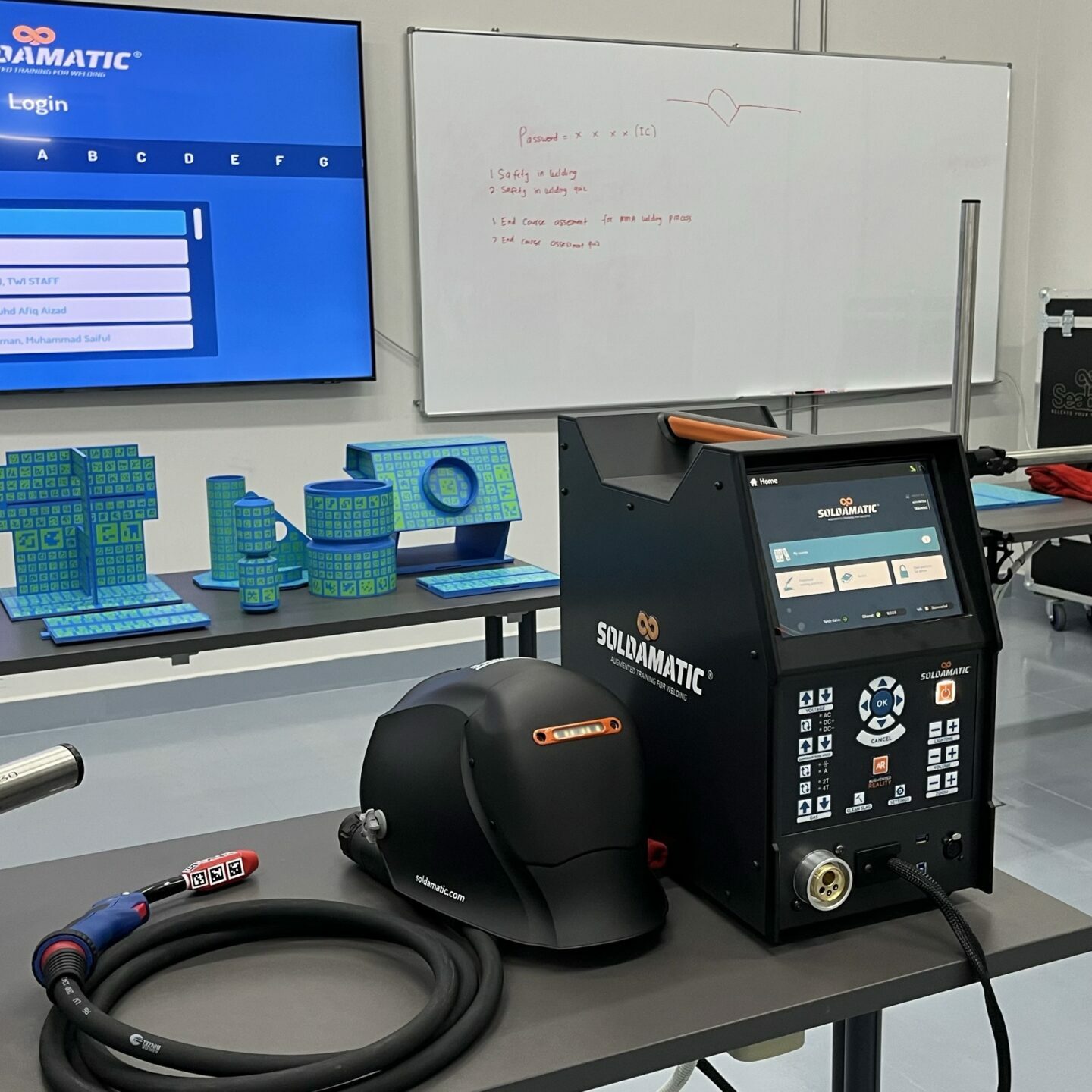

As part of its facilities in Kuala Lumpur, Malaysia, TWI has implemented an Augmented Lab with 5 Soldamatic 5.0 units. This facility will be used for blended advanced welder training through courses offered by TWI.

Comparison between a Welding Course and a Certification

As part of its objectives, TWI seeks to offer its members the latest developments and technologies in simulation. For this, they have relied on Seabery, and in particular on the most realistic welding simulation on the market, the one offered by Soldamatic thanks to its HyperReal-SIM.

Soldamatic allows the training of inexperienced welders, offering a 100% safe environment in which they can develop their muscle memory using real materials before moving on to the real welding workshop.

In addition, TWI is implementing Soldamatic for blended advanced welder training. For this purpose, it has several advanced welding parts (AWMs), which allow them not only to prepare welders for real jobs in the industry, but also to test the level of experienced welders in different processes, positions and specifications.

With this new technology, TWI hopes to attract more welders to the profession, and reduce the time it takes to train the competent and certified welders that industry needs.

In the video case study below you can see how TWI is using this Soldamatic Augmented Lab, as well as hear first-hand impressions from Tat-Hean Gan (TWI Director of Membership and Innovation) and the TWI team responsible for welding training and certification.

Earlier this year, Seabery and TWI signed a collaboration agreement to bring Soldamatic technology to all TWI members. You can read more about this agreement here.