Spray painting is a core process across industries such as automotive repair, manufacturing, metalworking, construction, and industrial maintenance. Whether you are refinishing vehicle parts, restoring machinery, or performing coating work in a workshop, proper spray painting safety practices are essential. These environments expose painters to fumes, chemicals, overspray, pressurized equipment, and physical risks that require structured preventive measures. Ensuring safety is not only about protecting workers’ health—it also improves coating quality, minimizes rework, and supports environmental compliance.

This article outlines the essential spray painting safety tips that every worker, trainer, or facility manager should know, followed by how augmented reality solutions elevate safety and efficiency in modern spray-painting education.

Why Safety Matters in Spray Painting

Spray painting involves atomizing paint into fine particles, which can pose hazards when inhaled or when they land on the skin or eyes. Many coatings contain chemicals such as solvents, isocyanates, and volatile organic compounds (VOCs). Exposure can lead to respiratory issues, skin irritation, long-term health conditions, and fire hazards.

According to the Occupational Safety and Health Administration (OSHA), improper ventilation, lack of PPE, and inadequate training are among the most common causes of spray-painting-related accidents. Good safety practices protect workers from chemical exposure, improve the work environment, and ensure compliance with regulations.

Consejos esenciales de seguridad en la pintura en spray que todos deberían conocer

1. Use Proper Personal Protective Equipment (PPE)

Wearing PPE is the first line of defense against chemical exposure and airborne particles. Essential PPE for spray painting includes:

- Respirators with appropriate filters

- Chemical-resistant gloves

- Safety goggles or full-face masks

- Protective coveralls

- Safety boots

Respiratory protection is vital, especially when working with high-pressure equipment or materials containing isocyanates. OSHA recommends regularly checking respirator fit and maintaining filters to ensure full protection.

2. Ensure Proper Ventilation

Adequate airflow prevents inhalation of toxic particles and reduces the buildup of flammable fumes. Spray booths, extraction systems, and cross-ventilation techniques ensure operators work in a safer environment.

High-volume, low-pressure (HVLP) systems, for instance, reduce overspray and environmental contamination while improving transfer efficiency. Even in open workshop environments, airflow should be monitored to maintain safe working conditions and avoid paint accumulation.

3. Manage Flammable Materials Carefully

Many paints, thinners, and solvents are flammable. It is essential to:

- Keep materials away from ignition sources

- Follow proper storage guidelines

- Dispose of rags and materials soaked with solvents correctly

- Avoid overheating electrical components

Industrial fires caused by improper paint handling are a well-documented risk, making compliance with fire safety rules indispensable.

4. Maintain Equipment Regularly

Spray guns, hoses, nozzles, and compressors must be regularly inspected and cleaned to avoid:

- Clogging

- Paint defects

- Equipment malfunction

- Unexpected overspray or leaks

Equipment maintenance protects workers, ensures greater efficiency, and prevents sudden breakdowns that may lead to accidents.

5. Practice Safe Techniques and Correct Body Positioning

Even with proper equipment, unsafe habits can lead to injury. Operators should learn:

- Correct distance from the surface

- Proper gun angle

- Consistent movement speed

- Trigger control

These techniques not only ensure safety but also improve coating quality. Manual errors often result in defects such as sagging or orange peel, which can waste material and require costly rework.

6. Be Aware of Environmental Impact

Traditional spray painting is often polluting due to overspray, VOC emissions, and chemical waste. Using low-VOC paints, controlled environments, and modern spray technology helps reduce environmental impact and improve overall safety.

Key Spray Painting Hazards and Their Preventive Measures

|

||||||||||||||||||||

Seabery’s AR-Based Spray Painting Training: A Safer Way to Learn

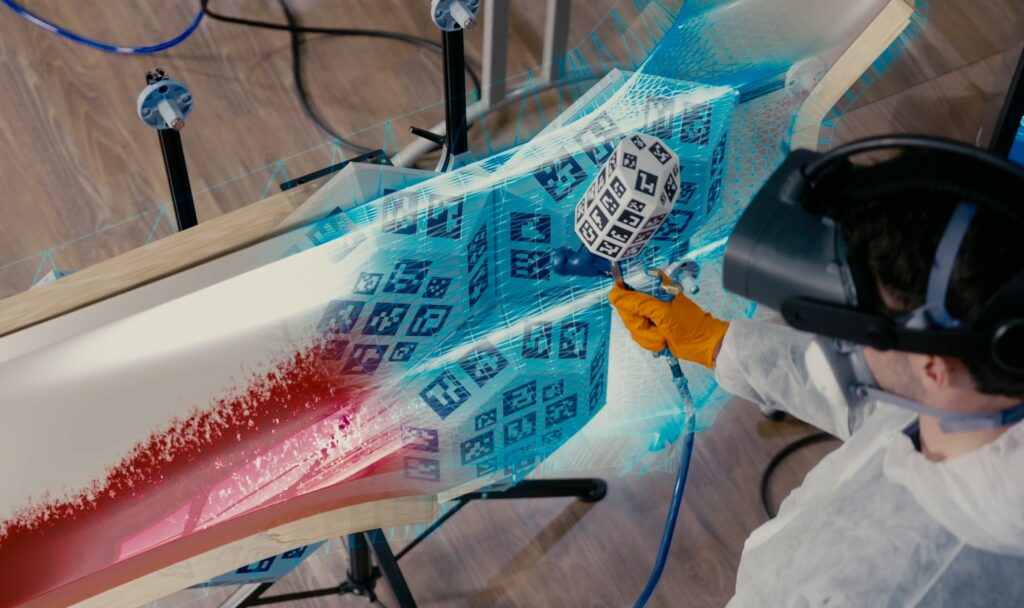

Training is a critical part of spray painting safety. One of the most effective ways to reduce risks in early learning stages is to remove exposure to hazardous materials altogether, this is where Seabery’s augmented reality (AR) spray painting training solution excels.

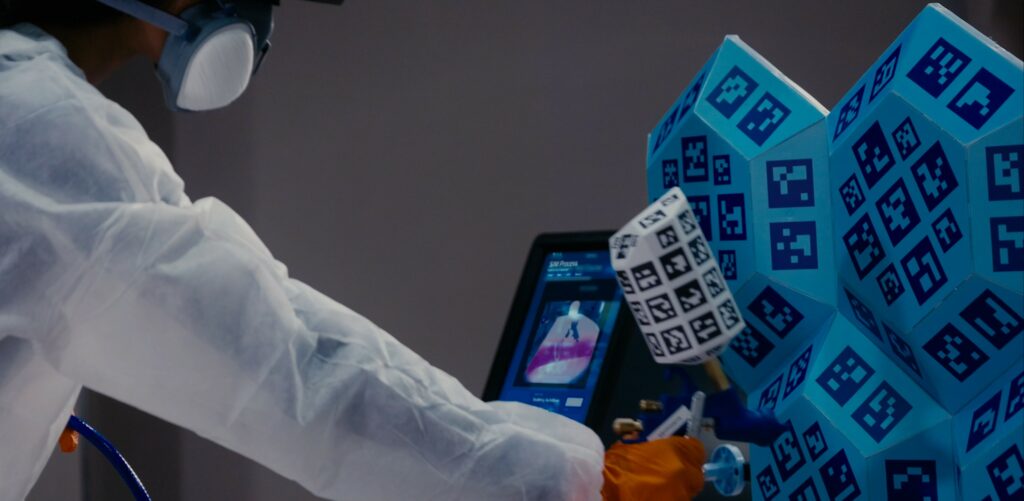

Seabery’s simulator provides a hyper-realistic environment where learners practice real movements using a real spray gun, authentic PPE, and standardized parts, all without the risks associated with real paint, chemicals, or fumes. The system includes:

- HyperReal-Sim™ technology for accurate stereoscopic AR rendering

- A realistic HTE spray gun with adjustable airflow, fan, and fluid controls

- Real-time visual guides that teach proper distance, angle, and speed

- Automated analysis of dry film thickness (DFT), coverage, paint consumption, and manual-skill-related defects such as orange peel and sagging

- A complete methodology that integrates simulator, LMS connectivity, and standardized industry curricula

Because no chemicals, fumes, or flammable materials are used, trainees can perform unlimited practice safely. This reduces accidents, minimizes contamination, and lowers costs—while accelerating skill development and improving safety compliance.

Seabery Spray Painting simulator’s approach ensures that students and workers build strong muscle memory and safe handling habits before entering real spray booths. This results in safer workplaces, better coating quality, and more efficient learning programs across educational centers and industrial sectors.

Safety First, Quality Always

Spray painting safety is essential for protecting health, ensuring quality, and maintaining a productive work environment. From proper PPE and ventilation to equipment maintenance and correct technique, every detail contributes to safer operations.

Modern tools such as Seabery’s AR spray painting training system allow organizations to reduce risks, lower costs, and train talent more efficiently, making high-quality, safety-focused learning accessible to everyone.