Traditional welding methods often come with significant safety risks and environmental concerns. To address these challenges, the industry is increasingly turning to innovative technologies and sustainable practices. This article explores best practices that leverage automation and digitalization to enhance safety and minimize environmental impact in industrial welding.

Implementing effective waste management strategies

Welding operations generate various forms of waste, including metal scraps and hazardous fumes.

Implementing efficient materials management and recycling programs can significantly reduce waste output. Proper segregation, labeling, and storage of waste materials are essential to prevent environmental contamination and ensure compliance with regulations. Additionally, optimizing welding processes to minimize material consumption and scrap production contributes to waste reduction and resource conservation.

Utilizing eco-friendly materials and consumables

The selection of materials and consumables significantly impacts the environmental footprint of welding operations.

Transitioning to water-based fluxes and low-emission electrode coatings can reduce the generation of harmful fumes and toxic waste. Moreover, using recycled metals and alloys in welding projects can decrease the environmental impact associated with mining and smelting, further promoting sustainability.

These eco-friendly alternatives not only improve environmental outcomes but also enhance workplace safety.

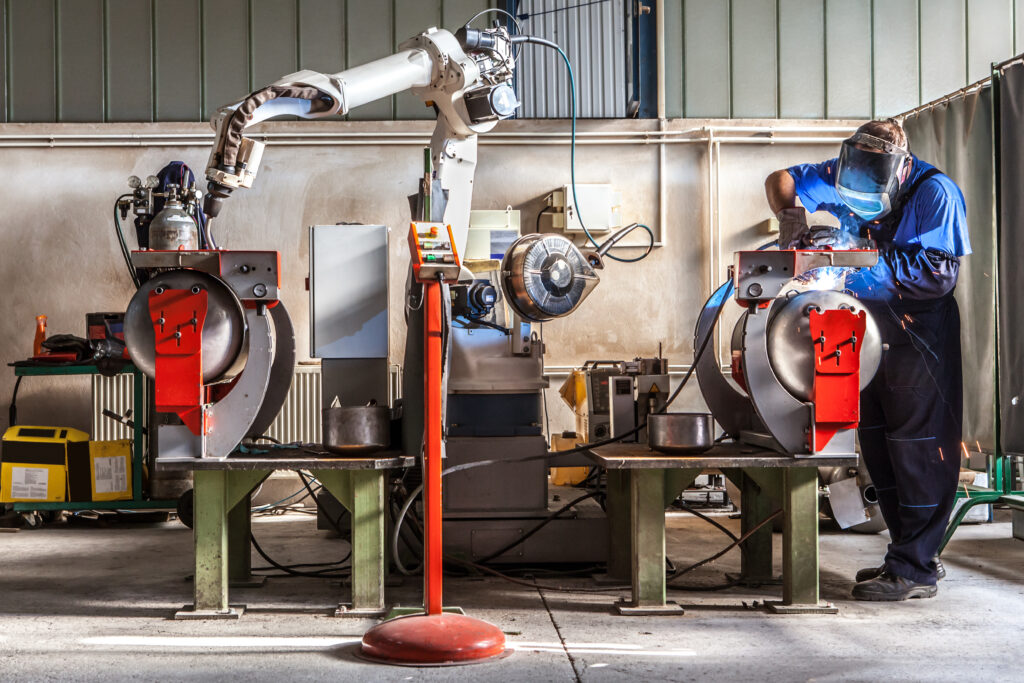

Leveraging automation and robotics

Automation in welding processes plays a crucial role in enhancing safety and sustainability.

Robotic welding systems equipped with advanced sensors can perform tasks with high precision, reducing material waste and energy consumption. These systems also minimize human exposure to hazardous environments, improving overall workplace safety. Cobots are designed to work alongside humans safely. In welding, they can assist with repetitive or hazardous tasks while humans focus on complex or strategic aspects.

Automation allows for consistent quality and efficiency, which is essential in meeting the demands of modern manufacturing while adhering to environmental regulations.

Enhancing training and certification programs

Educating welders about sustainable practices is vital for widespread adoption. Training programs that incorporate modules on energy-efficient techniques, proper material selection, and environmental regulations can empower welders to implement green practices effectively. Certification programs that include criteria for sustainable practices further encourage the industry to prioritize environmental responsibility.

Embracing Augmented Reality (AR) for enhanced safety

Augmented Reality is revolutionizing welding safety by providing real-time, context-sensitive guidance to welders. Seabery’s technology is designed with a strong focus on proper personal protective equipment (PPE) use, and we always recommend wearing welding gloves during training. Our solution incorporates torches supplied by Abicor Binzel, ensuring a highly realistic experience, without the safety risks of live welding.

Seabery Welding Simulator can overlay step-by-step instructions and gives immediate feedback. The simulator also provides a safer training environment, reducing the risk of accidents and making training more accessible. This allows and empowers welders to make safer decisions on the job site.

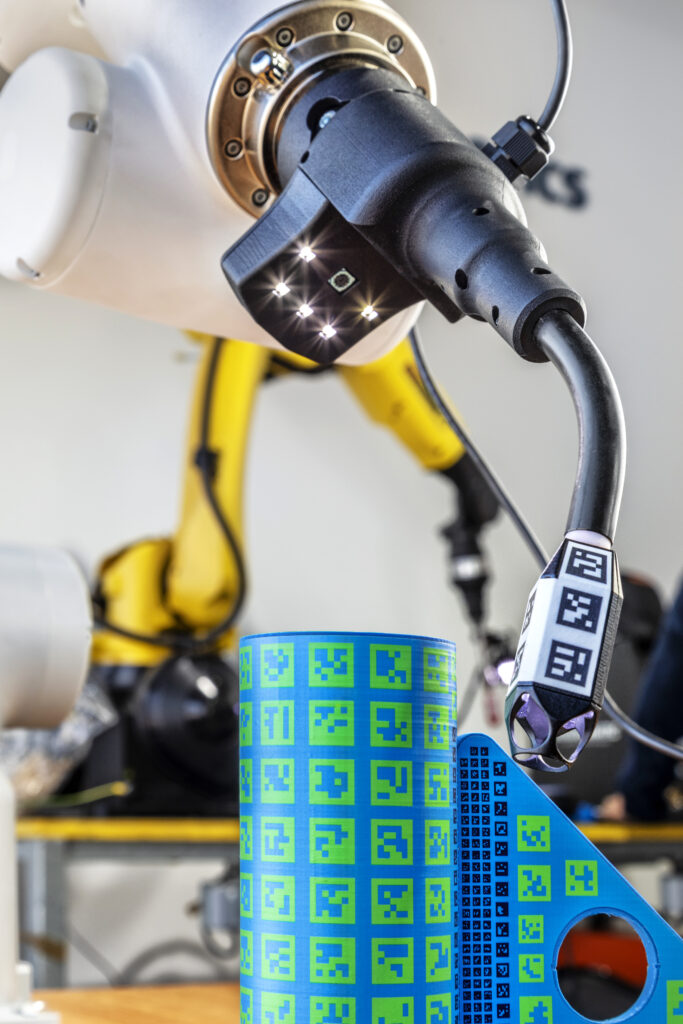

The usage of cameras with sensors and digital platforms to monitor welding parameters (temperature, arc stability, gas flow…) in real time allows early detection of anomalies. This proactive approach minimizes defects, reduces material waste, and helps ensure compliance with safety standards.

Soldamatic offers a comprehensive, scalable, and environmentally sustainable training solution that bridges the gap between theoretical knowledge and hands-on experience. The system offers robust instructor software that facilitates real-time monitoring of trainee’s performance, course management, and assessment. Instructors can design custom exercises, analyze welding techniques, and provide immediate feedback, enhancing the overall training effectiveness.

Implementing welding simulators for sustainable training

Traditional welding training consumes significant resources and generates waste. Our welding solution offers a sustainable alternative by providing a virtual environment where trainees can practice without consuming materials or producing emissions. Environmentally, Seabery’s technology significantly cut down on CO₂ emissions by minimizing the need for physical materials and energy-intensive processes.

The simulator accurately replicates a wide range of welding practices (including processes, joint types, and positions) enabling skill development in a resource-efficient way. Welders can move on to real-world practice only after achieving the required score in the AR exercises.

By integrating welding simulators into training programs, organizations can reduce their environmental footprint and lower training costs, all while maintaining high training standards.

Where safety meets sustainability

Improving safety and reducing environmental impact in industrial welding requires a multifaceted approach that embraces technological advancements and sustainable practices. The welding industry can achieve significant progress toward a safer and more sustainable future if these practices are applied.

By incorporating ESG principles into welding training, Seabery aims to reduce environmental impact and promote social responsibility.