Key Pipeline Welder Skills You Need

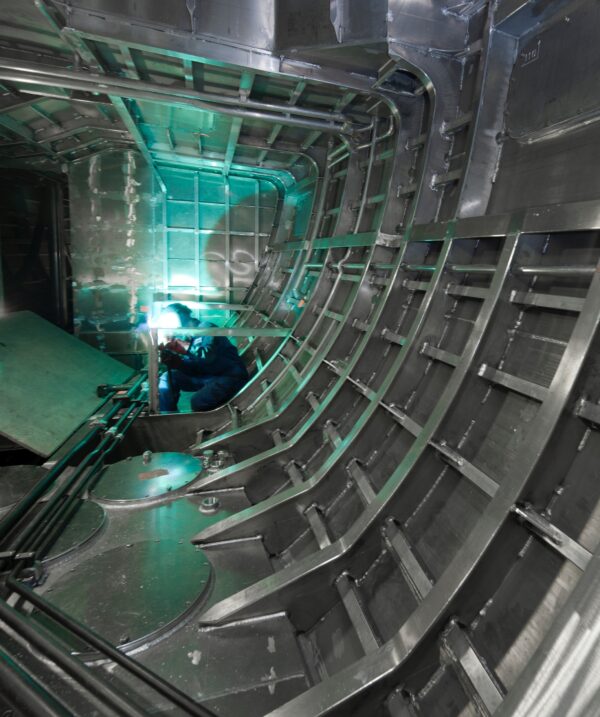

Pipeline welding is one of the most demanding and specialized disciplines in industrial welding. Whether in oil & gas, petrochemical plants, power generation, or large-scale infrastructure projects, pipeline welders are responsible for ensuring the integrity, safety, and longevity of critical systems. A single defect can lead to costly downtime, environmental damage, or serious safety risks.…