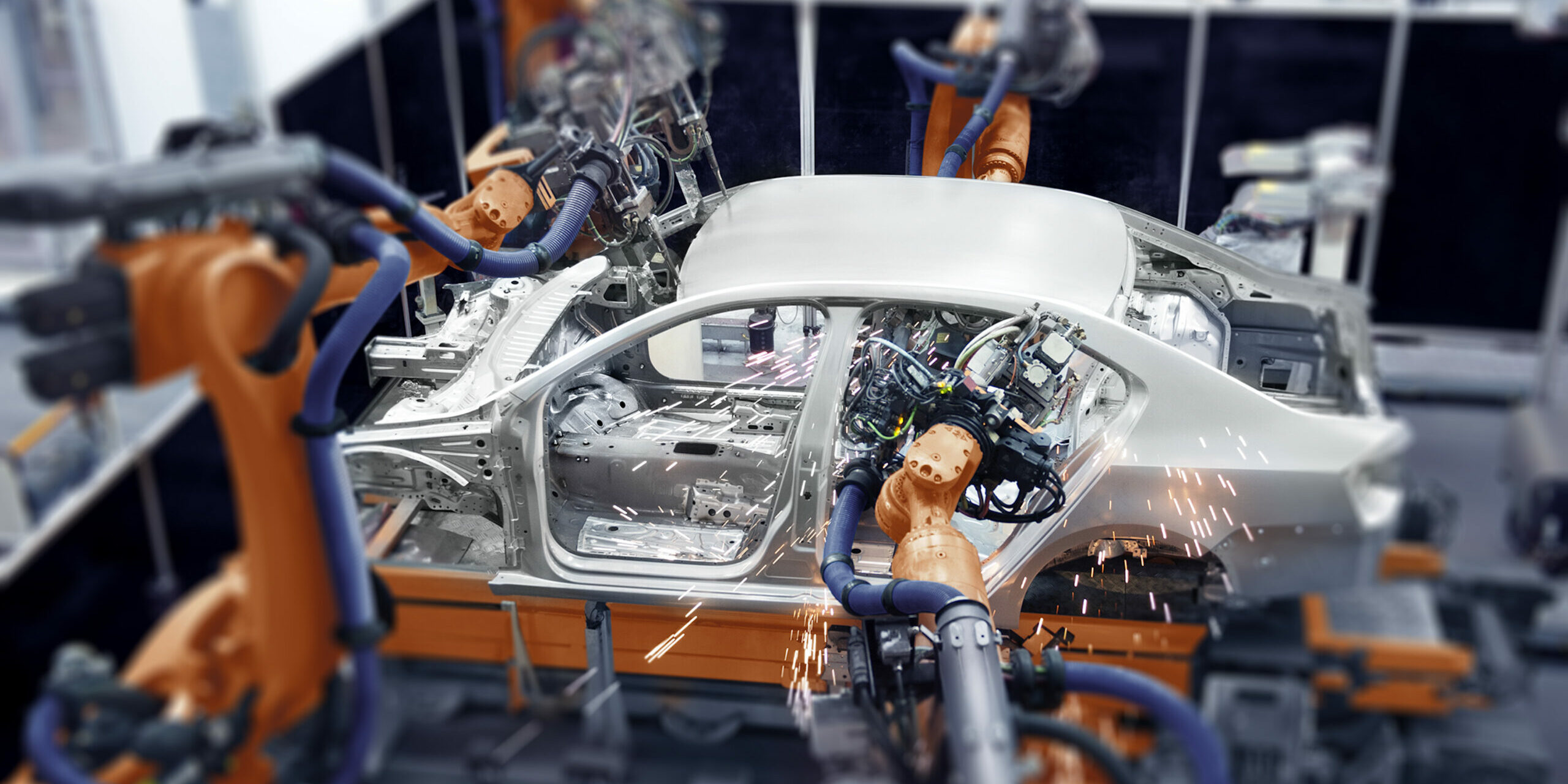

In the era of Industry 4.0, the automotive sector is undergoing rapid transformation through digitalization, automation, and advanced materials. Welding remains a core process in vehicle manufacturing and repair; whether in body-in-white, chassis, battery enclosures or structural assemblies.

To keep pace, training in automotive welding must evolve: combining traditional hands-on methods with augmented reality (AR), real-time feedback, simulation, and data-driven methodologies. In this article, we explore current trends in automotive welding training and best practices for delivering effective programs.

Trends in automotive welding training

Advanced welding processes and materials

The automotive industry is experimenting with new welding processes and materials (for example: aluminum, higher strength steels, dissimilar metals). Other processes such as laser welding, friction stir welding (FSW), and ultrasonic welding are gaining attention due to minimal heat distortion and improved strength.

In training curricula, it is increasingly necessary to cover these advanced processes and help learners understand material interactions, joint design challenges, and parameter optimization.

Sustainability and cost efficiency

Reducing waste, lowering energy consumption, and minimizing consumables are key drivers in automotive manufacturing. Training programs are responding by integrating methods that decrease material use and emphasizing efficient welding strategies.

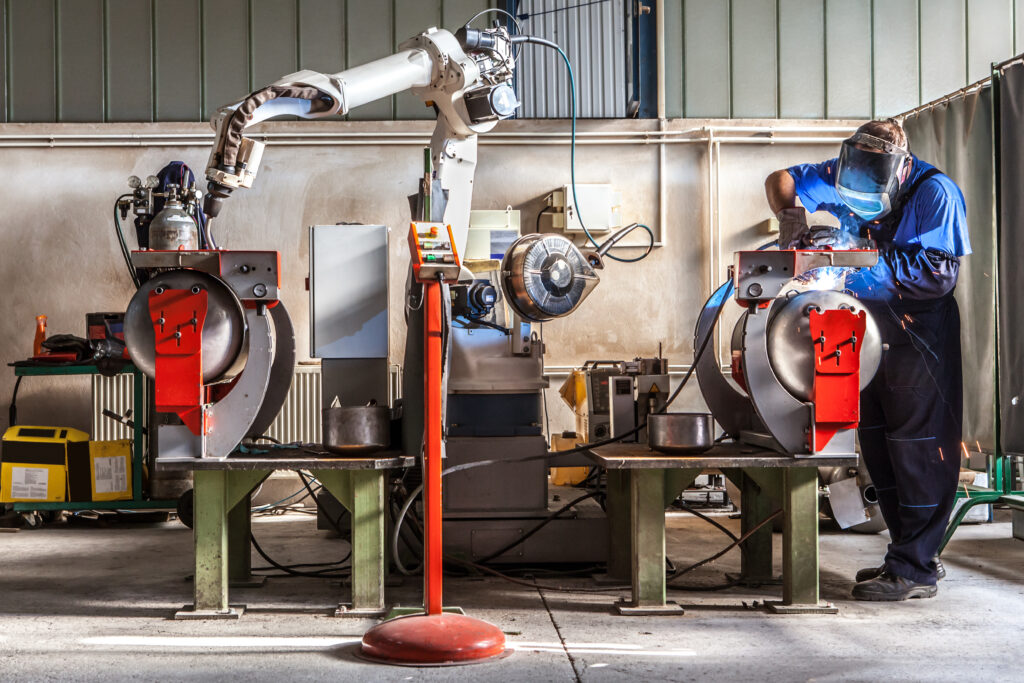

Automation, robotics and collaborative robots

As automotive production increasingly uses robotic welding for high throughput and consistency, training must also include robotic welding programming, maintenance, and human-robot collaboration. Cobots are gaining traction in welding cells to assist with tasks like material positioning, improving throughput while maintaining safety.

In training programs, simulators are integrating with robotic control systems so trainees can practice programming and path planning before handling real robots.

Digitalization, data and smart welding systems

“Smart welding” systems; machines equipped with sensors, IoT connectivity, and predictive analytics, are becoming more common. These systems monitor variables in real time (arc stability, temperature, deposition rate) and can enable adaptive control or early fault detection.

In training, this means exposing beginners to systems that log welding metrics, offer dashboards, and let trainees analyze process data to improve technique.

Integration of mixed reality and self-paced learning structures

One of the most important developments is the use of augmented reality (AR) and virtual reality (VR) in welding training. These immersive technologies let trainees practice in a risk-free environment, simulate multiple welding processes and joints, and receive real-time feedback on technique (angle, speed, arc length) without consuming materials.

For example, blending AR with physical welding instruction has shown to shorten the learning curve and reduce consumables usage. In welding education programs, AR simulators are used to offer unlimited practice, automated scoring, and error correction before trainees move onto real arcs.

Research into psychomotor skill acquisition also supports AR/VR as effective complement to traditional training methods. Rather than rigid classroom schedules, training programs are increasingly adopting modular structures that mix theory, simulation, lab, and field phases. Self-paced modules, remote access to simulation, and blended approaches (online + in-shop) help learners progress flexibly.

Best practices for automotive welding training

To make automotive welding training effective, here are recommended practices:

Combine robotic and manual welding training: Ensure that curricula include both traditional manual welding and robotic welding (or cobot) training. Let learners program robot paths, simulate robot welds, and understand handoffs between human and machine operations.

Use a variety of joint types, positions and materials: Expose trainees to the full spectrum of automotive weld types, such as spot welds, seam welds, overlap joints, T-joints, fillets, dissimilar materials, and sheet metal positions. This breadth builds adaptability. Allow learners to revisit modules, practice repeatedly, and choose specializations. Use blended online theory with in-workshop labs.

Emphasize safety, quality and inspection skills: Teach non-destructive testing (NDT) methods, weld inspection, defect recognition, and process control metrics as integral parts of the training, not just welding technique.

Industry alignment and certification: Design the program so it aligns with automotive industry standards and certifications, (for example: European Federation for Welding, Joining and Cutting, or OEM requirements).

Scaffold learning from simulation to real welding: Begin learners on AR/VR simulators to build basic technique without risk, then progressively transition them to real welding tasks. This scaffolding reduces errors, material waste, and frustration

Incorporate real-time feedback and metrics: Provide dashboards, scoring, and visual cues so trainees can self-correct. Track metrics over time to monitor improvement and highlight problem areas (travel speed, oscillation, arc length variance). Given that automotive welding technologies evolve, the curriculum must be reviewed periodically. Collect feedback from trainees, instructors, and industry partners to iterate.

How Seabery aligns with these trends

Seabery welding solutions are built around augmented reality methodology, which directly supports many of the trends and best practices above.

This simulator allows learners to practice welding virtually, with real-time visual cues, scoring, and immediate feedback; reducing the need for consumables and errors. Because the platform replicates different welding processes, joint types, positions, and materials, it supports scaffolded learning from simulation to real welding.

By minimizing waste, reducing error risks, and encouraging repeat practice without physical equipment costs, Seabery helps institutions maximise training resources.

The welding simulator can be part of blended and modular curricula, aligning training with evolving industrial requirements in automotive welding.

Seabery’s solution is well placed to support the trajectory of automotive welding training: digitally enhanced, feedback-driven, safe, and efficient.

Driving welding excellence in automotive training

As the automotive sector embraces lighter materials, stricter quality standards, and higher volumes, welding training must be agile, tech-savvy, and practical. The leading approaches combine AR/VR simulation, real-time feedback, exposure to robotic and smart systems, and adaptable modular curricula.

By adopting these best practices, and leveraging solutions like Seabery Welding Simulator, training programs can prepare welders who are not just competent yesterday, but skilled for the demands of tomorrow.