In today’s industrial landscape, digitalization and automation are transforming every corner of the production process, including how professionals are trained. The demand for highly skilled spray painters is increasing, yet traditional training methods often fall short: they are costly, risky, time-consuming, and environmentally unsustainable. This is where Augmented Reality (AR) technology is making a decisive difference, reshaping the way we develop practical skills in industrial coating applications.

From risky workshops to digital training labs

Traditional spray painting training has long been associated with several challenges. It is a process that requires expensive consumables, ventilated spaces, and strict safety measures to protect trainees from exposure to hazardous materials. On top of that, errors during practice lead to material waste and pollution, making the process inefficient and environmentally unfriendly.

AR Spray Painting simulators eliminate these issues by offering a risk-free and eco-conscious training environment. Instead of spraying real paint, trainees use a real spray gun connected to an augmented reality platform, which reproduces realistic scenarios and surfaces without generating any waste or emissions. This digital shift means lower costs, shorter learning curves, and a safer path to mastery.

How Augmented Reality transforms spray painting training

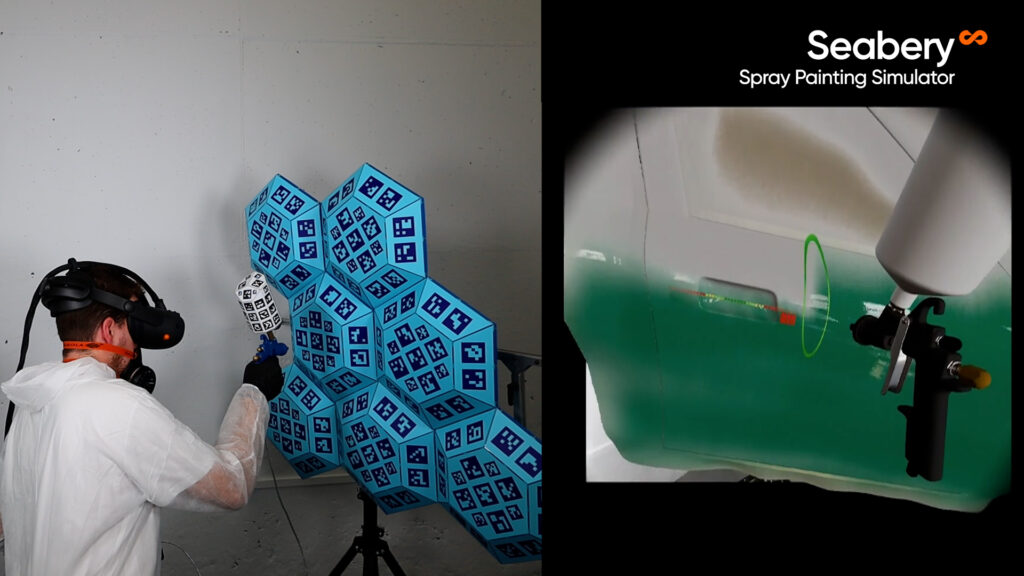

The AR Spray Painting Simulator developed by Seabery represents a new generation of immersive, hands-on learning. It blends real-world equipment with cutting-edge digital simulation, allowing users to perform actual spray-painting movements while visualizing results in real time through an AR headset.

Unlike traditional virtual reality (VR) systems that isolate users in a virtual world, AR preserves their awareness of real surroundings, which is essential when developing manual skills and muscle memory.

HyperReal SIM

The simulation itself is powered by Seabery’s HyperReal SIM™ technology, which delivers:

- Real spray guns with real weight, controls, and air flow dynamics.

- Authentic personal protective equipment (PPE), so trainees can move naturally within a real training space.

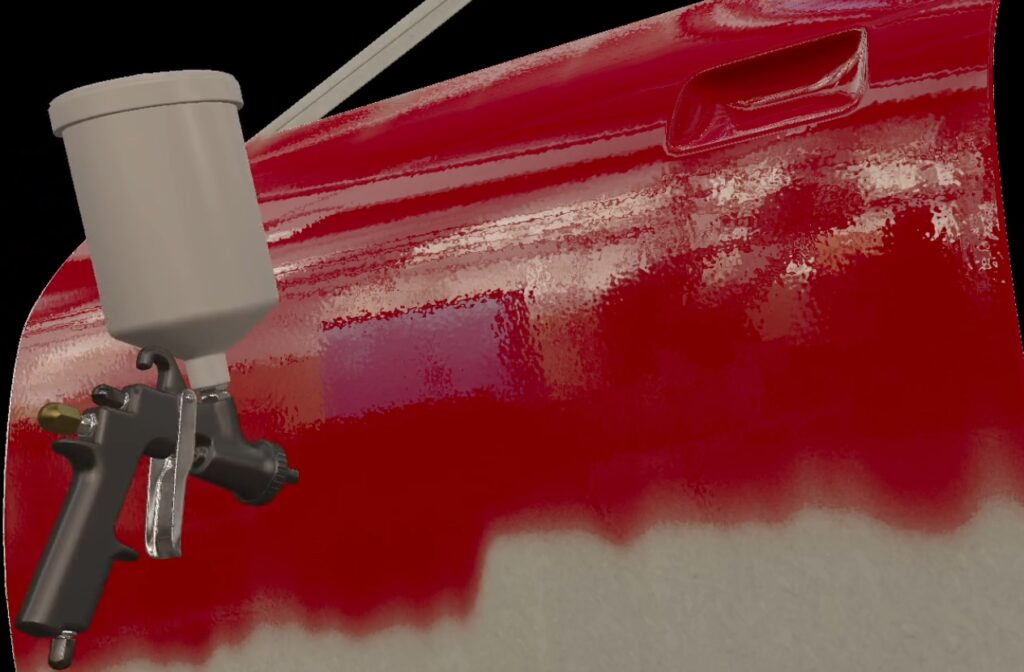

- High realism graphics based on Physically Based Rendering (PBR) and ray-tracing for accurate light and material behavior.

- Realistic sound and haptic feedback, reproducing the spray noise and feel of different paint systems.

- Parts based on most common used in industry. Use of ModulAR components, interchangeable workpieces that replicate the shapes, surfaces, and geometries found in actual manufacturing and automotive environments. This ensures that trainees gain experience on realistic pieces, developing muscle memory.

- Precise defect analysis, highlighting issues such as orange peel, sagging, or excessive thickness in real time.

- Simulation based on real testing.

- 3D analysis and scoring to assess each student’s manual skills, such as angle, speed, and distance.

This approach ensures that every exercise directly contributes to skill development, with instant feedback and performance analytics driving continuous improvement.

A comprehensive methodology for modern training centers

Beyond the hardware and AR visualization, Seabery Spray Painting Simulator includes a complete training methodology designed to streamline the learning process. Through LMS (Learning Management System) integration, instructors can create courses, assign exercises, and track each student’s progress remotely.

The platform supports:

- Exercise customization (choice of workpiece, coating type, difficulty level).

- Real-time performance review through detailed analysis modules.

- Gamification features such as rankings and challenges to boost engagement.

This methodology transforms training centers into connected, data-driven learning environments, where instructors can easily manage multiple students of varying levels, even across different locations.

Digitalization and sustainability: The new industrial standard

The adoption of AR Spray Painting simulation aligns perfectly with the global trend toward industrial digitalization and sustainability. By minimizing the use of consumables such as paint, solvents, and compressed air, training programs can drastically reduce carbon footprint and environmental impact.

At the same time, companies benefit from cost reductions and higher efficiency in workforce upskilling. According to Seabery’s internal studies, AR-based training can cut learning time by while increasing knowledge retention thanks to repetitive, feedback-rich practice.

This digital approach also supports the transition toward Industry 4.0, where automation, connectivity, and intelligent systems work together to create smarter, safer, and more productive industrial environments.

Why Seabery leads the AR training revolution

Seabery has established itself as a global leader in AR-based industrial training solutions, with a presence in more than 80 countries. The spray painting simulator exemplifies its mission: to bridge the gap between traditional craftsmanship and digital innovation.

Built “by painters, for painters”, the simulator ensures that every detail, from gun control to visual rendering, faithfully replicates real-life conditions. Combined with Seabery’s modular hardware design, cloud-based LMS, and proven augmented methodology, this solution stands out as the most realistic and effective spray painting simulator available.

By integrating AR into the training process, Seabery empowers institutions and companies to:

- Enhance safety

- Reduce costs.

- Accelerate learning outcomes.

- Standardize skill assessment.

- Prepare a new generation of painters ready for smart, sustainable industry.

Augmented Reality — Shaping the Future of Painting

Seabery Spray Painting Simulator marks a pivotal step forward in how manual skills are taught and perfected. Through the power of Augmented Reality, training becomes immersive, efficient, and environmentally responsible, paving the way for a new era of industrial education.

As industries continue to embrace digital transformation, Seabery’s solutions demonstrate how technology can preserve craftsmanship while enhancing performance, ensuring that the painters of tomorrow are ready, skilled, and sustainable.