Pipeline welding is one of the most demanding and specialized disciplines in industrial welding. Whether in oil & gas, petrochemical plants, power generation, or large-scale infrastructure projects, pipeline welders are responsible for ensuring the integrity, safety, and longevity of critical systems. A single defect can lead to costly downtime, environmental damage, or serious safety risks. This article explores the key pipeline welder skills you need to succeed in today’s industrial environment.

Understanding the role of a pipeline welder

Pipeline welders specialize in joining pipes that transport liquids and gases under high pressure and extreme conditions. These welds must meet strict industrial standards and are often inspected using advanced non-destructive testing (NDT) methods.

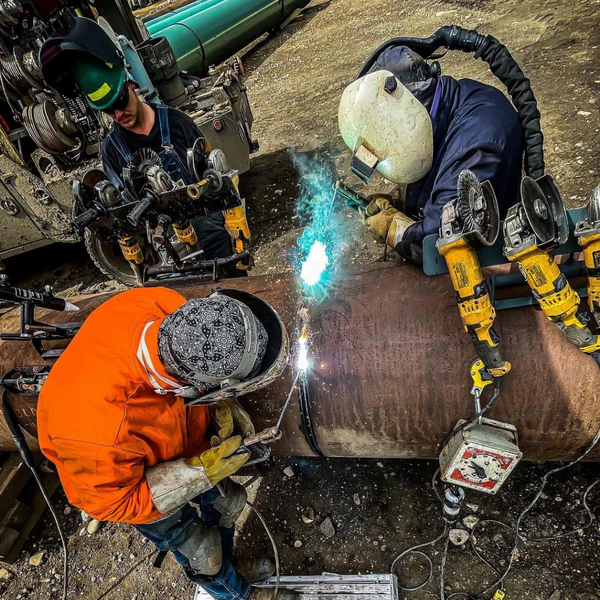

Unlike workshop welding, pipeline welding frequently takes place outdoors, in remote locations, and under challenging conditions. This makes skill, precision, and adaptability absolutely essential.

Core technical welding skills

1. Mastery of welding processes

A pipeline welder must be proficient in several welding processes, including:

- SMAW (Shielded Metal Arc Welding) for root and fill passes.

- GTAW (TIG welding) for high-quality root welds.

- FCAW and GMAW in automated or semi-automated industrial environments.

Understanding when and how to apply each process is fundamental to producing defect-free welds.

2. Pipe position and joint preparation

Pipeline welding typically involves complex positions such as 5G and 6G, requiring exceptional control and consistency. Skills include:

- Accurate pipe alignment and fit-up.

- Proper beveling and joint preparation.

- Control of penetration and bead profile.

Mistakes at this stage often lead to failures during inspection.

Quality, inspection, and standards awareness

3. Knowledge of codes and standards

Pipeline welders must work in compliance with international standards such as those issued by organizations like the American Welding Society and ISO. This includes understanding:

- Welding Procedure Specifications (WPS).

- Acceptance criteria for weld defects.

- Documentation and traceability requirements.

4. Defect prevention and self-inspection

Top pipeline welders are proactive in preventing defects such as lack of fusion, porosity, or cracking. Skills include:

- Reading weld puddle behavior.

- Adjusting parameters in real time.

- Performing visual inspections before NDT.

This mindset reduces rework and increases productivity.

Physical and environmental skills

5. Working under harsh conditions

Pipeline welding often takes place in extreme heat, cold, wind, or confined spaces. Welders need:

- Physical endurance.

- Strong hand–eye coordination.

- Focus and consistency over long shifts.

Safety awareness is also critical, particularly in hazardous industrial environments.

Methodology and process discipline

6. Following structured welding methodologies

Modern industrial welding emphasizes standardized methodology over improvisation. Pipeline welders must be disciplined in:

- Following defined welding sequences.

- Respecting heat input limits.

- Maintaining consistency across multiple joints.

This process-driven approach aligns welding quality with broader industrial quality systems.

Digitalization and automation skills

7. Adapting to digital welding environments

Digitalization is rapidly transforming industrial welding. Today’s pipeline welders increasingly interact with:

- Digital WPS and data logging systems.

- Automated or orbital welding equipment.

- Performance tracking and quality analytics.

Understanding how welding parameters are recorded and analyzed is becoming a core skill, not an optional one.

8. Collaboration with automated systems

Automation does not replace pipeline welders, in fact it enhances them. Skilled professionals are needed to:

- Set up and supervise automated welding systems.

- Interpret system feedback.

- Intervene when conditions change.

This hybrid skillset bridges manual expertise with industrial automation.

Training, learning, and skill development

9. Continuous learning mindset

Pipeline welding standards, materials, and technologies evolve constantly. Successful welders commit to:

- Regular certification updates.

- Training on new materials and processes.

- Performance assessment and improvement.

Learning is no longer limited to apprenticeships—it is a lifelong process.

10. Training with Augmented Reality and welding simulators

One of the most significant innovations in welding training is the use of augmented reality (AR) welding simulators. These systems allow welders to:

- Practice complex pipeline welding scenarios without consumables.

- Receive immediate, objective performance feedback.

- Train safely before entering high-risk industrial environments.

Simulation-based training improves consistency, reduces training costs, and accelerates skill acquisition—especially for critical pipeline welding positions.

Building industry-ready pipeline welders with advanced training solutions

Developing high-level pipeline welding skills requires more than repetitive practice. Industrial environments demand consistency, traceability, and measurable performance, especially when working under strict codes, complex positions, and high-risk conditions. This is where advanced training technologies play a key role in closing the gap between traditional learning and modern industrial requirements.

Seabery Welding Simulator is designed to address the exact challenges pipeline welders face today through a structured, data-driven, and simulation-based approach; by combining augmented reality, industrial welding methodology, and digital performance analytics.

Standardized training for critical pipeline weld positions

Pipeline welding often involves highly demanding positions such as 5G and 6G, where minor deviations can result in failed inspections. Seabery enables training centers and industrial organizations to standardize training exercises across these critical scenarios.

Using augmented reality welding simulation, trainees can repeatedly practice pipe welding positions, joint configurations, and welding sequences under controlled conditions. This standardization ensures that all welders are trained according to the same methodology, reducing variability and improving overall weld quality once they move to real-world projects.

Objective skill assessment and performance measurement

One of the main challenges in traditional welding training is the subjectivity of evaluation. Seabery addresses this by integrating digital performance analytics into the training process. Welders not only improve their manual skills but also develop an understanding of how welding data is generated, analyzed, and used to support quality control and continuous improvement in industrial projects.

The welding simulator captures key parameters such as travel speed, torch angle, arc length, and heat input; and translates them into objective performance metrics. This allows instructors and industrial supervisors to:

· Identify skill gaps early.

· Track individual progress over time.

· Compare performance against predefined industrial criteria.

This data-driven approach is especially valuable for pipeline welding, where compliance with procedures and repeatability are critical.

Safe and cost-effective training for industrial environments

Pipeline welding training typically requires significant material consumption, specialized facilities, and exposure to safety risks. Augmented reality simulation provides a safe and cost-efficient alternative for skill development without compromising realism.

By reducing the need for consumables, real pipes, and live arc exposure during early training stages, organizations can optimize training costs while maintaining a strong focus on safety. Welders gain confidence and muscle memory before entering demanding field environments.

Skills that go beyond the weld

Pipeline welding is no longer just about laying a good bead. It requires a combination of technical expertise, process discipline, adaptability, and digital skills. As industrial welding moves toward greater digitalization and automation, pipeline welders are increasingly expected to interact with digital tools, automated systems, and performance monitoring platforms.

Pipeline welding is not a one-time qualification: it requires continuous upskilling as standards, materials, and procedures evolve. Seabery supports ongoing training and recertification processes by enabling repeatable practice and performance benchmarking over time. This makes the solution suitable not only for initial training, but also for experienced welders who need to refresh skills, adapt to new procedures, or prepare for qualification tests under industrial codes.

The key pipeline welder skills you need today extend far beyond traditional welding techniques. Mastery of processes, understanding industrial standards, adapting to automation, and committing to continuous learning are what define the modern pipeline welding professional. Investing in advanced training solutions is not just an advantage: it is a necessity for the future of industrial welding.