Spray painting is a critical industrial process that goes far beyond aesthetics. In sectors such as automotive manufacturing, aerospace, metal fabrication, and industrial maintenance, the quality of spray painting directly impacts product durability, corrosion resistance, safety, and overall brand perception. As environmental regulations tighten and quality standards rise, professional spray painting training has become an essential investment rather than an optional one.

Modern spray painting training must balance theory, hands-on practice, safety awareness, and process optimization. Traditional training methods, however, often struggle with high material costs, environmental impact, and limited opportunities for repeated practice. This is why the way professionals are trained in spray painting is rapidly evolving.

Why Spray Painting Training Is a Core Professional Skill

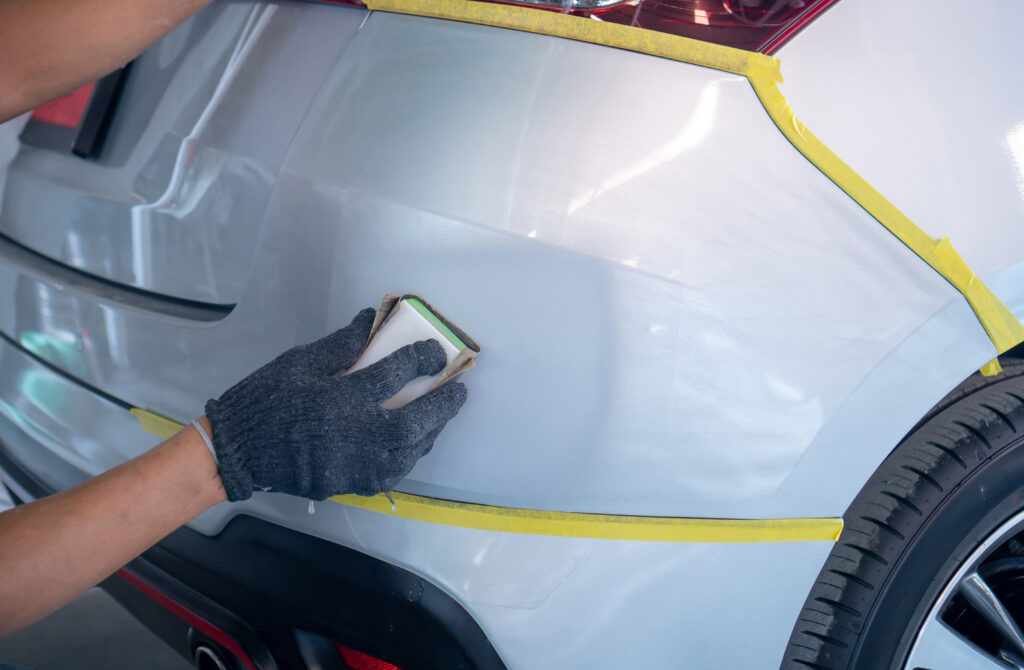

Spray painting is a manual skill that requires precision, consistency, and deep process understanding. Small variations in distance, angle, speed, or overlap can lead to defects that compromise quality and increase rework costs.

Professional spray painting training focuses on developing several key competencies:

- Gun handling and control: Maintaining correct distance, angle, and speed.

- Surface preparation knowledge: Understanding how substrates and pre-treatments affect adhesion.

- Coating behavior: Knowing how different paints, primers, and varnishes behave.

- Defect prevention: Identifying and avoiding issues such as orange peel, sagging, or insufficient coverage.

- Safety and compliance: Working safely with hazardous materials and complying with industry regulations.

Organizations such as Occupational Safety and Health Administration and ISO emphasize proper training as a key factor in reducing workplace accidents and ensuring consistent industrial quality. According to OSHA guidelines, inadequate training is one of the main contributors to accidents in paint booths and finishing workshops.

Common Challenges in Traditional Spray Painting Training

While hands-on practice is essential, traditional spray painting training comes with significant drawbacks:

1. High operational costs

Paint, solvents, filters, and protective equipment are expensive. Repeated practice quickly increases material consumption.

2. Environmental impact

Overspray, VOC emissions, and waste disposal make conventional training environmentally challenging. This is increasingly problematic in regions with strict environmental regulations, such as those aligned with the European Environment Agency.

3. Health and safety risks

Exposure to chemicals and particles poses risks, especially for beginners who are still learning proper techniques.

4. Limited feedback

In many training environments, feedback depends heavily on instructor observation, which can be subjective and time-limited.

5. Restricted practice time

Due to costs and safety constraints, students often get less practice time than needed to fully develop muscle memory.

These limitations have driven the search for more efficient and scalable training methods.

Key Skills Developed Through Modern Spray Painting Training

Professional spray painting training programs aim to standardize skills while allowing for individual learning curves. The most effective programs focus on measurable performance indicators.

| Skill Area | Description | Impact on Quality |

| Distance control | Maintaining optimal gun-to-surface distance | Uniform coating thickness |

| Angle consistency | Keeping a stable spray angle | Reduced overspray and defects |

| Speed regulation | Controlling gun movement speed | Even coverage and finish |

| Path overlap | Managing stroke overlap | Consistent appearance |

| Defect recognition | Identifying visual and thickness issues | Reduced rework and waste |

By breaking down spray painting into these measurable components, training becomes more objective and results-driven.

Digitalization and Simulation in Spray Painting Training

Digitalization is transforming how manual industrial skills are taught. Simulation-based training, especially when combined with real tools and environments, allows trainees to practice intensively without the usual constraints.

According to a study referenced by McKinsey & Company, simulation-based training can reduce training time by up to 40% while improving skill retention. This is particularly relevant for spray painting, where repetition and immediate feedback are crucial for developing muscle memory.

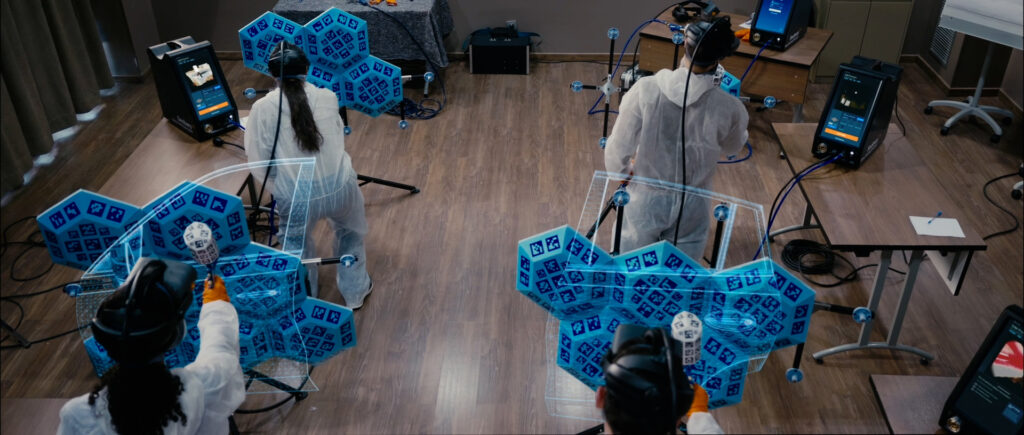

Augmented reality (AR) has emerged as a particularly effective approach because it allows trainees to:

- Use real spray guns with authentic weight and controls.

- Train in real physical spaces, not virtual-only environments.

- Receive objective, data-driven feedback on every movement.

- Practice without paint, solvents, or emissions.

These advantages make AR especially suitable for manual skills training.

The Value of Seabery Spray Painting Simulator

At the forefront of this transformation is the Seabery Spray Painting Simulator, an advanced augmented reality training solution designed specifically for professional spray painting education. Unlike purely virtual systems, it combines real equipment with high-fidelity AR simulation.

The simulator allows trainees to work with real spray guns, authentic personal protective equipment, and industry-relevant parts, while the augmented reality layer provides visual guidance and performance analysis. Training exercises are based on real industrial painting processes and parameters, enabling learners to practice safely and repeatedly.

Key benefits include:

- Reduced costs by eliminating paint and consumables during training.

- Environmental sustainability, with zero emissions and waste.

- Objective performance analysis, including dry film thickness and defect detection.

- Increased training time, allowing students to practice more without additional risk.

This approach aligns perfectly with modern industrial training needs and supports standardized, scalable education across training centers and companies worldwide.

Training for Quality, Safety, and Sustainability

Spray painting training is no longer just about learning how to apply paint—it is about mastering a complex, safety-critical, and quality-driven industrial skill. As industries demand higher standards and more sustainable practices, training methods must evolve accordingly.

By combining structured skill development with advanced technologies such as augmented reality, professional spray painting training can become more efficient, safer, and environmentally responsible. Solutions like the Seabery Spray Painting Simulator represent a significant step forward, helping organizations train highly skilled painters while reducing costs, risks, and environmental impact.

Investing in modern spray painting training is, ultimately, an investment in long-term quality and industrial excellence.