In sectors where performance and precision are crucial – such as medicine, aviation, automotive or welding – simulation has become a highly valuable tool. More and more professionals are turning to it to practice procedures, train complex situations and improve their skills without affecting the real operation. Its usefulness transcends initial training and has become a key element for qualification, specialization and continuous improvement.

Today, not incorporating these simulation technologies in training means remaining anchored in the past, while adopting them allows advancing towards higher standards of professionalization and competitiveness.

Simulators: a standard in demanding training

Medicine: millimetric precision that saves lives

In surgery, interventional cardiology or anesthesiology, simulators allow physicians to practice complex procedures without risk to real patients. Through controlled scenarios, they can perfect decision-making in critical situations, reinforce protocols and gain fluency in highly specialized techniques.

Aviation: training the exceptional to avoid real incidents

Airline pilots regularly train in simulators to deal with emergencies, sudden changes in conditions or system failures. Simulation is mandatory in their certification and recertification process, even when they have already accumulated thousands of flight hours.

Automotive pilots: every millisecond counts

In Formula 1, WEC or rally, simulators allow teams to adjust strategies, analyze vehicle behavior and prepare drivers for new circuits or stages. Simulation speeds up the learning curve, reduces testing costs and improves performance consistency.

Welding: when quality is critical and every weld matters

Traditionally, soldering has been trained on real material, with consumables, risks and time constraints. But the industry has been calling for years for more efficient, safer, measurable and scalable training.

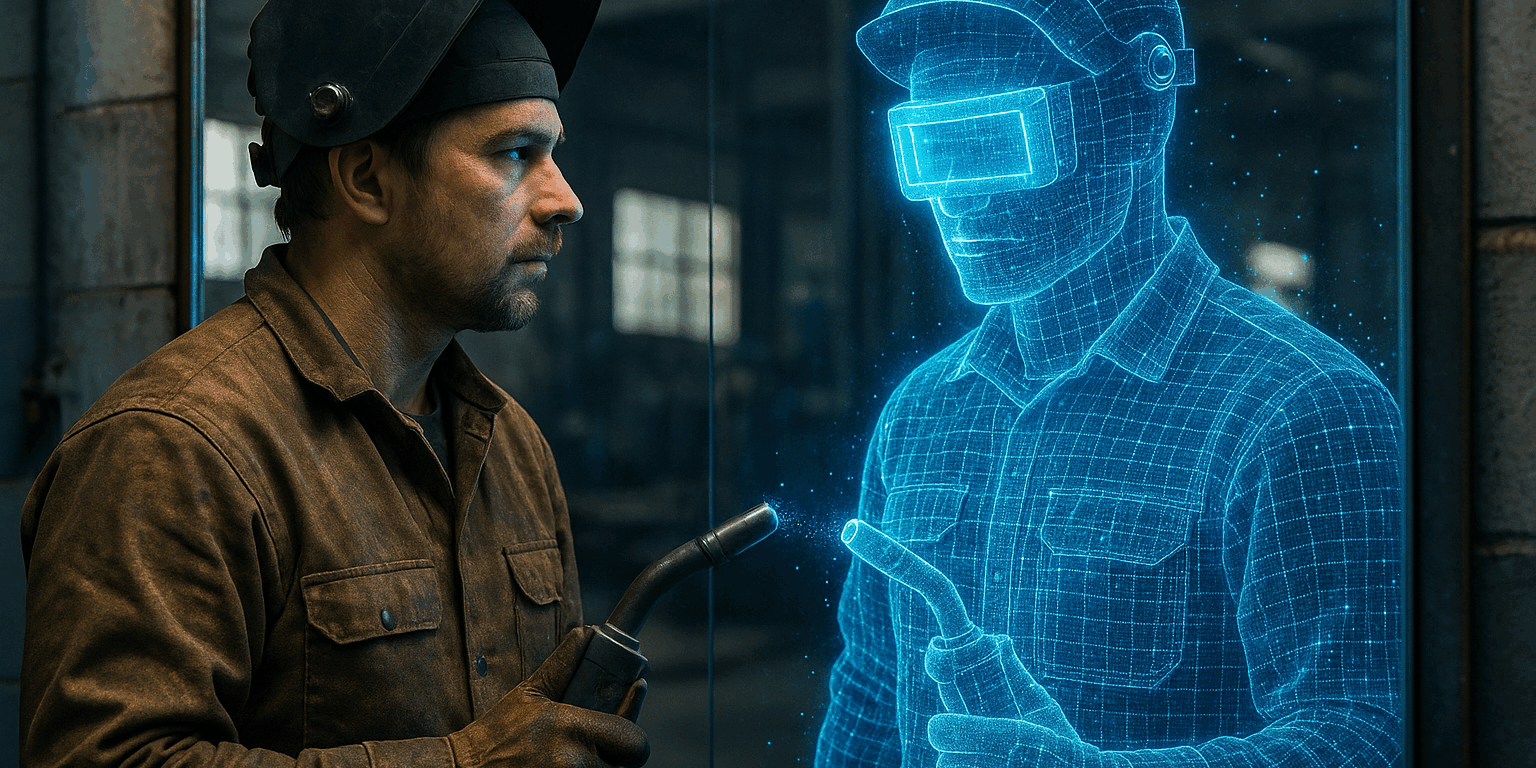

Augmented reality answers this need, allowing welders to practice all types of processes and positions without material waste and with full traceability of their progress. This not only improves training: it also revalues welders by allowing them to demonstrate their technical mastery through objective data and evidence of their progression.

The digital twin of the welder: precision, data and professional excellence

Professional welders training with simulation in UK

The Welder’s Digital Twin, developed by Seabery as part of the Welding PRO service, is an example of how advanced simulation is transforming the way professional performance is assessed and improved.

This technology makes it possible to:

· Measure the technical performance of each welder using objective and comparable parameters.

· Detect specific areas for improvement, helping to achieve higher quality standards.

· Generate reports based on real data, essential for qualification processes or internal audits.

· Facilitate specialization in new techniques and positions without affecting production.

· Provide clear evidence of professional competence, which is increasingly valued by the industry.

In addition, mastering these tools provides welders with added value: their profile becomes more attractive and sought after by companies, especially in sectors where precision and efficiency are decisive.

Keeping up to date with simulation enhances the value of professional welders

As is the case in other highly demanding sectors, professionals who integrate simulation into their training stand out for their ability to adapt, their focus on continuous improvement and their use of advanced technologies.

In welding, this reality translates into professionals who know and master simulation:

· They gain greater visibility thanks to objective metrics of their performance.

· Deepen their technical mastery, reducing errors and gaining consistency.

· Demonstrate commitment to innovation, which is especially valued in leading companies.

· They increase their employability and attractiveness in sectors such as automotive, naval, railway or aeronautics.

Simulation not only allows them to learn better: it allows them to differentiate themselves.

Conclusion

Simulation has become an essential tool for improving skills, reducing risks and reinforcing professional qualifications in many sectors. In the field of welding, technologies such as augmented reality and the welder’s industrial twin are raising training and production standards.

Keeping abreast of these innovations not only optimizes individual performance, but also enhances the welder’s profile and increases his attractiveness to companies. At Seabery, we work to make this technological evolution accessible, useful and transformative for training centers, professionals and industrial companies.