Achieving a flawless finish in spray painting is both a science and an art. Whether in automotive refinishing, industrial manufacturing, or maintenance operations, spray painting requires a deep understanding of materials, tools, and methodology. Today’s industrial standards demand not only aesthetic quality but also precision, repeatability, and efficiency. As automation and digitalization reshape the sector, mastering high-quality spray painting techniques has become essential for both new learners and experienced professionals looking to refine their skills.

This article explores the top spray painting techniques that ensure perfect results, the principles behind them, and the modern training methods that help painters build real-world competency faster and more safely than ever before.

Preparing the Surface: The Foundation of a Perfect Finish

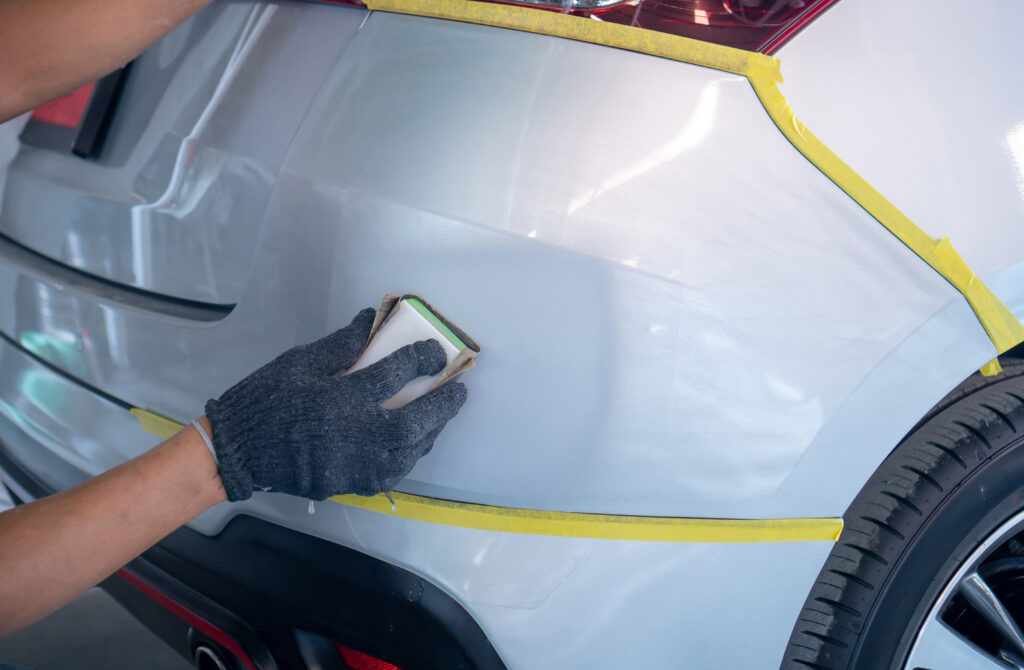

The first and most crucial step in achieving an excellent spray painting outcome is surface preparation. Any imperfection, dust, grease, corrosion, or uneven textures, will be amplified once the paint is applied. Proper preparation usually includes:

- Cleaning the surface with appropriate degreasers.

- Sanding to create a uniform base.

- Applying primer to ensure adhesion and long-lasting durability.

In industrial environments, surface prep is essential to avoid costly rework or material waste. This process also minimizes common defects like poor adhesion, uneven coverage, and premature paint failure.

Mastering Distance, Angle, and Speed

Spray painting is a manual skill that depends heavily on three critical variables: distance, angle, and speed. Keeping the spray gun at the correct distance ensures even paint distribution, while maintaining a consistent angle prevents streaking or excessive buildup. Likewise, painting too fast or too slowly can cause issues such as:

- Orange peel texture (from improper distance or angle).

- Sagging or dripping (from moving too slowly or being too close).

Selecting the Right Spray Pattern and Fan Adjustment

Different tasks require different spray patterns. Adjusting the fan control knob helps tailor the paint output to the job at hand:

- Wide fan patterns are ideal for large, flat surfaces.

- Narrow patterns work best on curved or small parts.

Modern spray guns include adjustable controls for airflow, fan size, and fluid delivery to help painters understand how these parameters impact coating quality .

Controlling Paint Thickness and Coverage

One of the most important goals in spray painting is applying the correct dry film thickness (DFT). Too thin, and coverage will be insufficient; too thick, and defects such as sagging can appear. Professional painters typically work with:

- Smooth and overlapping passes (often 50% overlap).

- Layer-by-layer application (base coat, color coat, varnish).

- Systematic checking of coating thickness.

Understanding Paint Types and Application Systems

Each paint type behaves differently depending on viscosity, environmental conditions, and equipment settings. Common industrial spray systems include:

- HTE (High Transfer Efficiency)

- Airmix and Airless (widely used in industrial and automotive sectors)

The choice of system influences transfer efficiency, coverage, and finishing texture.

Maintaining a Clean and Efficient Workflow

Professional finishers always work with a systematic, clean environment. This includes:

- Proper PPE.

- Consistent lighting.

- Controlled ventilation.

- Organized workstands and parts.

Keeping consistency is key to obtaining repeatable and predictable results, especially in industrial settings where quality audits require precise documentation of every step.

Seabery’s Augmented Reality Solution: Empowering Modern Spray Painting Training

Seabery’s augmented reality methodology enhances learning by focusing on the manual-skill-related defects that most commonly affect paint quality. These defects are key parameters measured in Seabery’s Spray Painting Simulator, where students can visually analyze how incorrect movement influences the final coating.

AR training solutions automatically analyze dry film thickness (DFT) and visualize thickness distribution in 3D, allowing learners to detect inconsistencies that are invisible to the naked eye. Because the choice of spray system influences transfer efficiency, coverage, and finishing texture, the AR platform integrates different application methods under standardized conditions, enabling future-ready training aligned with real industrial processes.

Example of a deffect in spray painting simulation.

| Defect | Cause | Impact on Finish | How AR Training Helps | ||

| Orange Peel | Incorrect distance, angle, or spray speed; improper viscosity | Textured, uneven surface | Visual guides for angle, distance, and speed help learners identify and correct improper technique | ||

| Sagging (Runs) | Excess paint application; slow gun movement; too close to the surface | Drips, streaking, loss of uniformity |

|

||

| Insufficient Coverage | Moving too fast or holding the gun too far from the surface | Patchy or transparent areas | Transfer efficiency metrics and coverage maps help visualize missed spots | ||

| Overspray | Excessive atomization; high pressure; improper fan adjustment | Dusty texture, paint waste | Parameterized exercises simulate fan and fluid control adjustments to minimize overspray | ||

| Uneven Thickness (DFT) | Lack of overlap; inconsistent movement | Lower durability; risk of peeling or fading | 3D dry film thickness analysis highlights inconsistencies not visible to the naked eye |

In addition to these advanced capabilities, Seabery’s AR-based Spray Painting Simulator provides a highly realistic user experience with stereoscopic rendering, authentic PPE, real-weight spray guns, and HD parametrized sound, immersing learners in a safe, controlled, and efficient training environment. It also offers LMS connectivity, standardized painting curricula, and a modular workpiece system (ModulAR) for flexible, scalable training configurations

Conclusion: Perfecting the Art of Spray Painting

Spray painting techniques continue to evolve, combining traditional craftsmanship with modern digital training approaches. Mastering fundamentals such as distance, speed, angle, DFT, and gun setup is essential for producing perfect finishes, especially in demanding industrial environments. As technology advances, new solutions like augmented reality simulators are reshaping how painters learn and practice, offering safe, efficient, and highly realistic pathways to develop professional skills.

Perfect Finish, Perfect Method: The combination of sound technique and innovative training tools empowers painters to achieve mastery faster, safer, and with consistent quality—exactly what today’s industrial world requires.