STEM (Science, Technology, Engineering, and Mathematics) Education is the foundation for innovation in the 21st century. Yet, one of its greatest challenges lies in keeping students engaged while helping them connect theoretical concepts with real-world applications. This is where welding in STEM education shines, turning abstract principles into tangible, hands-on experiences that spark curiosity, confidence, and creativity.

Welding: the hidden link between theory and real-world application

Welding it is a multidisciplinary process that combines physics, engineering design, materials science, and mathematics. Every weld is a practical application of STEM principles, from understanding heat transfer and electrical currents to calculating angles and material tolerances.

According to the National Science Teaching Association (NSTA), the integration of technical practices, like welding, strengthens students’ understanding of scientific concepts by placing them in real-world contexts. When students weld, they do not just follow instructions, they apply problem solving and analytical thinking to achieve precision and quality.

This hands-on approach helps young learners visualize how science and technology shape modern industries such as aerospace, automotive, and renewable energy, all of which depend on advanced welding processes. It also supports the Next Generation Science Standards (NGSS), which emphasize the importance of engaging students in engineering design and experimentation.

Hands-on learning: where STEM comes to life

Educators have long recognized that experiential learning boosts motivation and long-term retention. Research highlighted by Edutopia shows that students learn more effectively when they can experiment, build, and test ideas rather than passively consume information. Welding exemplifies this approach: it requires observation, adjustment, and feedback, the same cycle that drives scientific discovery.

When students learn welding in a STEM context, they develop:

- Critical thinking – understanding how heat and materials behave.

- Spatial reasoning – analyzing joint configurations and angles.

- Problem-solving – adapting techniques when outcomes vary.

- Collaboration – working in teams to design, test, and refine projects.

Moreover, introducing welding early provides an accessible gateway to technical careers. The National Science Foundation (NSF) supports initiatives that blend STEM with hands-on technical training, recognizing that skilled trades are vital for national innovation and economic growth.

The digital transformation of technical education

As technology advances, education must evolve with it. One of the most transformative trends is the integration of augmented reality (AR) and simulation into vocational learning. AR allows students to engage with realistic scenarios while minimizing risks, costs, and material waste: a major leap for both safety and sustainability.

In the context of welding, AR simulation brings the workshop to the classroom, allowing students to practice techniques, measure their progress, and visualize their performance in real time. These innovations align with STEM.org’s emphasis on technology-enhanced learning, which empowers students to apply theoretical knowledge in dynamic, interactive environments.

Through AR, students can explore complex processes safely, without the hazards of high temperatures or heavy equipment. This makes welding in STEM education not only more accessible but also more engaging for younger audiences.

Seabery STEM welding solution: inspiring future workforce

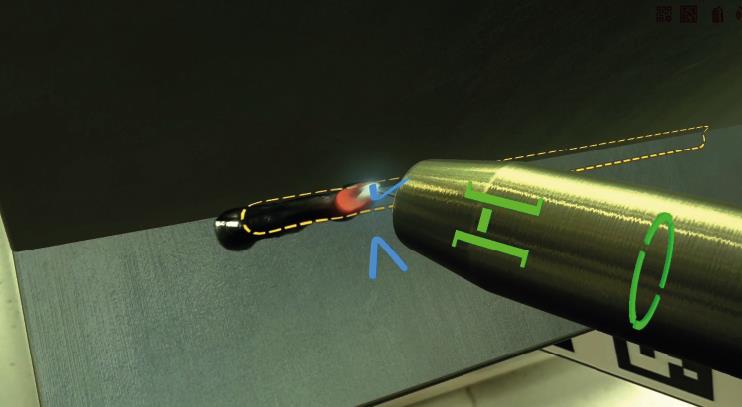

A pioneer in the field of educational technology, Seabery has developed an innovative AR-based welding simulator specifically designed for STEM education: Seabery STEM Welding. The solution combines real welding torches, physical workpieces, and helmet-mounted visualization systems to provide a fully immersive yet safe learning experience.

The simulator enables students to learn by doing, offering:

- Realistic torch handling and visual guides that replicate professional welding conditions.

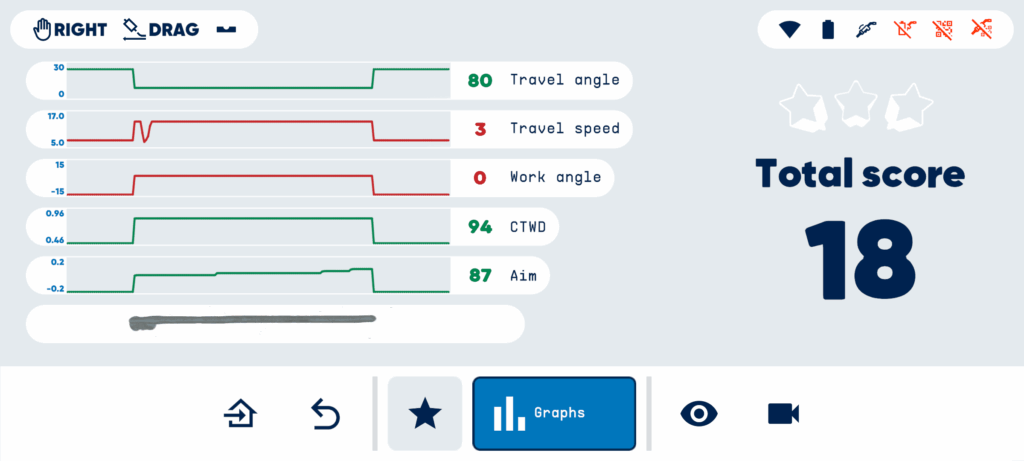

- Gamified exercises that make learning fun, interactive, and measurable.

- Wireless, battery-powered hardware for easy classroom integration.

- Scoring systems and content platforms that allow teachers to monitor progress and performance.

This setup lowers the barrier to entry, making welding accessible to students of all backgrounds. The experience helps them explore technical career paths and understand how engineering design, material science, and physics work together in practical applications.

Furthermore, Seabery’s augmented reality methodology ensures that each exercise builds both technical skills and cognitive understanding, bridging the gap between classroom theory and industrial practice. The result: a safe, cost-effective, and motivating way to introduce students to the world of engineering and manufacturing.

A Closer Look at Seabery’s STEM Welding Experience

Seabery’s STEM welding solution is designed as a fully portable, all-in-one educational kit that makes welding approachable for young learners. The system includes a mobile phone, a helmet with built-in AR visualization, and a real welding torch connected wirelessly to the mobile. Students can practice using different welding joints (T-joint, lap joint, butt joint), follow visual guidance, and instantly analyze their results on the mobile.

Thanks to its educational and gamified design, the simulator transforms complex technical training into a motivating experience, encouraging exploration and creativity. Teachers benefit from built-in content libraries, scoring systems, and progress tracking tools, which make classroom management simple and interactive. This approach not only helps schools introduce STEM through a modern lens but also inspires students to consider careers in engineering, robotics, and advanced manufacturing , vital industries for the digital economy.

Key benefits of welding in STEM education

| Benefit | Description |

| Bridges theory and practice | Demonstrates core STEM concepts through hands-on application. |

| Boosts engagement | Encourages active participation and experiential learning. |

| Promotes career exploration | Introduces students to high-demand technical professions. |

| Supports sustainability | With AR training, reduces material waste and energy use. |

| Enhances inclusivity | Accessible for all students, regardless of prior experience. |

Empowering the next generation of makers

Incorporating welding in STEM education is more than adding another tool to the curriculum: it is about giving students the confidence to create, test, and innovate. Welding connects abstract science to real results, showing learners that technology and craftsmanship go hand in hand.

By adopting Seabery STEM Welding, schools and training centers can cultivate a new generation of problem solvers, prepared not only to understand technology but to build it. As global industries face increasing demand for skilled professionals, early exposure to welding and related technical fields ensures students are ready to meet tomorrow’s challenges.

Welding does not just join metals: it connects curiosity with capability, learning with doing, and students with their future careers.