Welding is one of those essential industrial trades; foundations of many infrastructures, vehicles, machinery, buildings. A welder combines metals using heat, pressure, or both, working with materials like steel, aluminum, stainless steel, and more.

In today’s industrial landscape, welding does not just mean holding a torch and fusing metal: it is increasingly intertwined with technology, automation, digitalization, and new training methodologies. In this article we will explore what a typical day for a welder looks like, the advantages and disadvantages of the job.

A typical day for a welder

A welder’s day usually starts early. The worksite or factory opens, safety checks are done: PPE (personal protective equipment), ventilation, inspection of tools and machines. Welders review blueprints or welding plans, set up equipment such as choosing the right torch, selecting filler material, setting current/voltage/parameters. Afterwards they inspect the parts to be welded, adjust fixtures or clamps, and then carry out welds.

Between welding, there is preparation: cleaning surfaces, grinding, measuring, ensuring fit-ups are correct. Welders also inspect their own work, perhaps weld beads, look for defects, do touch-ups.

They may need to switch between different welding processes (MIG, TIG, stick, etc.), adjust for different positions (flat, vertical, overhead), often adapt to varying materials or geometries. Maintenance of tools, cleaning the workspace, safety checks, sometimes training or mentoring less experienced welders are part of the job.

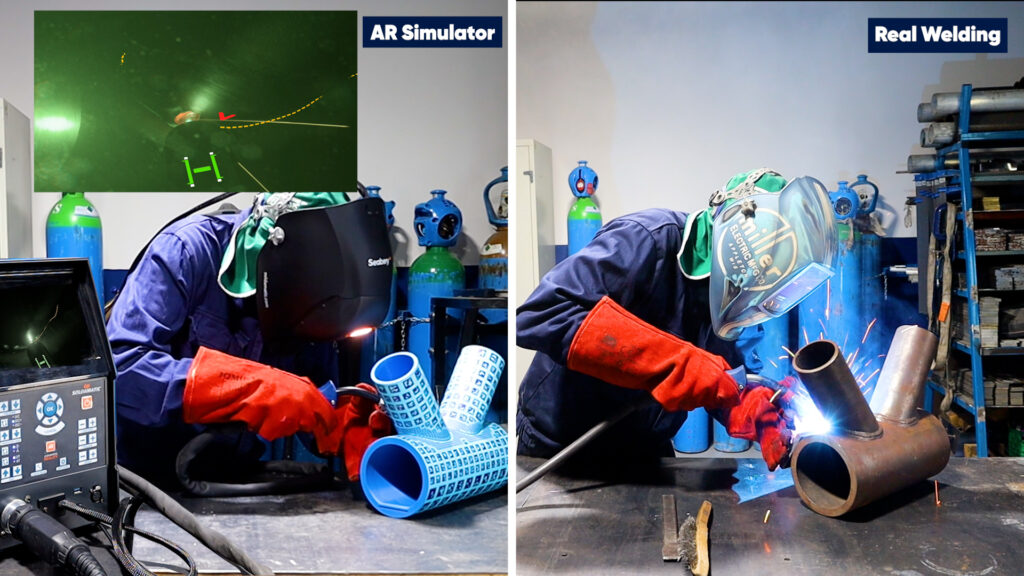

Welders in industrial settings often interact with automated systems or assist with robot setups; depending on the industry, they may be asked to calibrate or supervise robotic welding. In more advanced environments, digital tools, welding simulators, or augmented reality might be part of training or skill refinement.

Advantages of being a welder

Here are some of the benefits of this trade, especially in modern industrialized settings.

1. Demand for skilled welders

Welding is needed in construction, manufacturing, energy, shipbuilding, aerospace; so there tends to be fairly steady demand, especially for welders who are skilled and adaptable.

2. Diverse skills and variety

Welding offers variety in terms of materials, processes, positions, applications. No two jobs are exactly the same; for many welders, this variety is motivating.

3. Good earnings potential

Depending on specialization, location, industry, overtime, certifications, welders can earn well. Specialized types of welding (underwater, aerospace, etc.) or work with robotics/automation can increase pay.

4. Hands-on work

There is satisfaction in visible results: seeing a structure, part, pipeline welded together. Welding is a craft as much as industrial work.

5. Advances with technology and training

New tools: simulators, augmented reality (AR), welding simulation, digitalization of workflows, and robots help welders train more safely, quickly, and with fewer costly mistakes. For example, AR is being used to improve psychomotor skills, reduce consumable costs, provide instant feedback, etc.

6. Improved safety (when well managed)

While welding involves risks, better tools, protective equipment, automation, and simulator-training reduce exposure to hazards (heat, fumes, burns). Robotic welding can take over dangerous or repetitive tasks.

Challenges of the job

Even with its many positives, the welding profession has its drawbacks, especially in industrial and evolving tech settings.

1. Physical demands and environment

Welders face high heat, bright arcs (risk to eyes), fumes, noise, awkward positions, heavy materials. Repetitive motion, standing or crouching, working overhead: all strain the body.

2. Safety Risks

Burns, eye injuries, inhalation of toxic fumes, risk of fire, electrical hazards are real. Even with PPE, risk remains. In less regulated or poorly equipped workplaces, risk is magnified.

3. Learning curve and skill development

Welding is not trivial. Mastery takes time: learning to manage variables (angle, travel speed, current, filler, etc.). The training process can be long. Training, mentorship, hands-on experience is essential.

4. Exposure to technology and automation pressures

As factories automate more, welding jobs may change. Welders may need to learn to program or supervise robots, or shift their roles. For some, this is exciting; for others, it can be a stressor if they are less comfortable with digital tools. Also, maintenance, debugging, or programming robots require new skills.

5. Cost of equipment, tools, certification

Good quality PPE, tools, equipment, getting certified, possibly paying for training are costs. For newcomers, these can be a barrier. Also, mistakes are costly; scrap, rework cost time and materials.

6. Irregular work

Some welders work overtime, travel to different sites, work in adverse conditions (cold, wet, outdoors). Physical stress and exposure to elements or shift work can be taxing.

|

What a welder’s job is like |

|

|

Advantages |

Disadvantages |

| Job stability | Physical demands |

| Diverse skills and variety | Safety risks |

| Good earnings potential | Learning curve |

| Tangible output | Automation pressures |

| Advances with training | Costs |

|

Improved safety |

Physical stress |

Technology, methodology and digitalization

Modern welding is embracing various methodological and technological innovations:

- Augmented reality simulators are being used for safe, cost-efficient training. They help develop psychomotor skills, provide instant feedback, allow repetition without consuming materials.

- Automation / Robotic Welding: Full or semi-automated systems take over repetitive welds; improve consistency, throughput, reduce waste. However, they require high investment, technical know-how, reconfiguration for changes in design.

- Digitalization: Digital tools for planning, parameter tracking, quality monitoring, defect detection (some AI-based), and integrating data collection. This helps in optimizing welding processes, reducing rework, increasing quality.

- Methodology: Blended training (mixing hands-on with simulation), standardization of welding procedures, continuous evaluation, mentorship. These help reduce error, improve safety, raise skill level.

The Seabery advantage: safer, smarter welding training

Seabery augmented reality methodology offers an advanced solution aligning with the trends above. Here is how it stands out:

Immersive AR training: Seabery offers a welding simulator using augmented reality, where trainees interact in a virtual-real hybrid environment. This allows safe practice without risks of burns or hazardous fumes, before entering real welds.

Reduced costs and waste: By using simulation, less material is wasted training beginners; fewer consumables are needed, which saves money and environmental resources.

Adaptability to industrial needs: Seabery’s solution is built for industrial training, supporting different welding processes and preparing welders for industrial workflows. It helps bridge the gap between traditional hands-on welding and the increasing automation and digitalization in industry.

Real-time feedback and methodological strength: The simulator gives immediate feedback, tracks performance metrics, helps trainees refine technique (angles, speed, consistency, etc.) before errors become costly in real metal. Also good for standardizing training, ensuring welding methodology is followed.

Preparing welders for the future: Given that industry is moving toward automation, use of robotics, digital monitoring, Seabery Welding Simulator helps welders build skills relevant to that future; lessening the shock of having to adapt.

Industry transformation

Welding continues to be a trade of great importance in industrial sectors: a profession that combines craftsmanship, engineering, and evolving technology. On the one hand, welders enjoy hands-on work, job stability, and the satisfaction of building tangible things; on the other hand, the work can be physically challenging, potentially hazardous, and requires continuous learning, especially in a rapidly digitizing, automated environment.

As training methodologies evolve with augmented reality, simulators, and robotics, there is increasing support for welders to master the trade more safely, efficiently, and with lower cost. Seabery Welding Simulator exemplify this shift, enabling welders (and those who train them) to stay ahead of industrial transformation.

If you are considering welding as a career or managing training programs: embracing technology, keeping up with methodology, and investing in continuous learning will pay off in safety, quality, and adaptability.