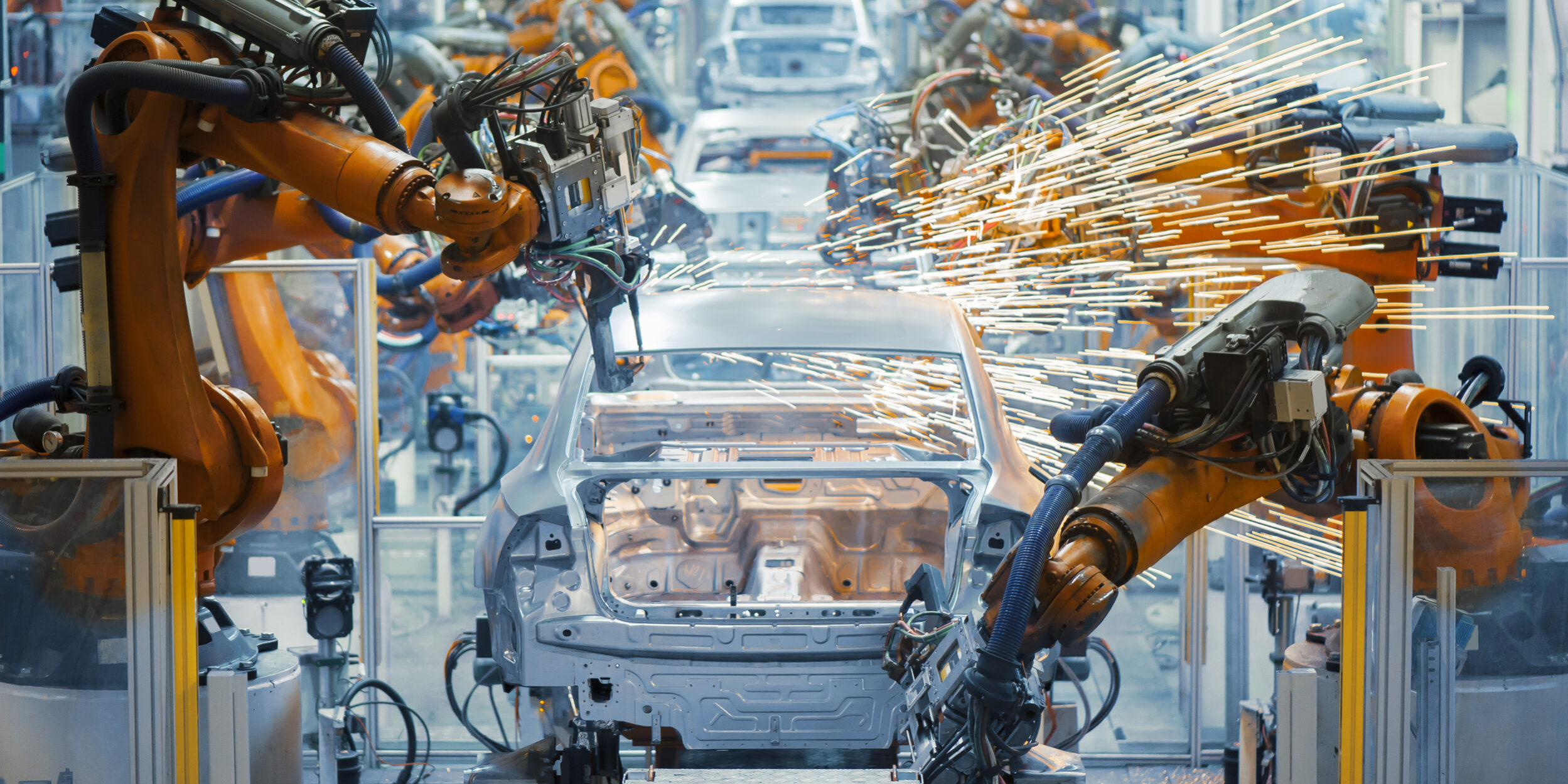

Welding processes are undergoing a profound transformation. Automation, digitalization, and cutting-edge technologies are reshaping how we join material; making operations faster, safer, and more reliable. Among these advancements, robotic welding has gained significant momentum.

By harnessing robotics, industries can address critical challenges including workforce shortages, quality variability, and escalating labor costs. This article explores the benefits of robotic welding and highlights how modern tech solutions are advancing its adoption.

1. Consistency and weld quality

A core advantage of robotic welding is its precision and repeatability. Unlike manual welds, which can vary based on fatigue or human error, robotic systems deliver uniform welds every time:

- Robots faithfully execute programmed parameters (speed, angle, arc settings) across all parts, significantly reducing weld defects and scrap.

- Studies affirm that robotic welds exhibit higher structural integrity and appearance than manual ones.

These consistent, high-quality outcomes are invaluable in sectors like automotive and aerospace, where stringent welding standards apply.

2. Productivity and throughput

Robotic welders dramatically enhance production capacity:

- They operate continuously (24/7) without breaks or fatigue, enabling faster cycle times and increased output.

- In job-shop settings, robotics accelerate operations from loading to unloading, optimizing material handling and workflow.

These factors translate into faster time-to-market and improved production scalability.

3. Cost reduction and waste minimization

While robotic systems involve upfront investment, long-term savings are substantial:

- High programming precision reduces material consumption and minimizes rework.

- Stable arc conditions and controlled parameters mean less spatter, diminishing post-weld cleanup efforts.

- Labor cost reductions are achieved by shifting skilled welders into oversight roles, reducing headcount.

Collectively, lower consumable use, reduced rework, and optimized labor lead to a leaner, more cost-effective operation.

4. Safety and ergonomics

Welding exposes workers to serious hazards such as burns, UV radiation, toxic fumes, heavy equipment, and ergonomic strain. Robotic systems effectively mitigate these risks:

- Robots perform the actual welding, allowing staff to monitor remotely and avoid immediate exposure.

- With fewer people near the weld zone, there is a marked reduction in workplace injuries and compensation incidents.

This safer environment not only boosts morale but also reduces liability and insurance costs.

5. Addressing the skills shortage

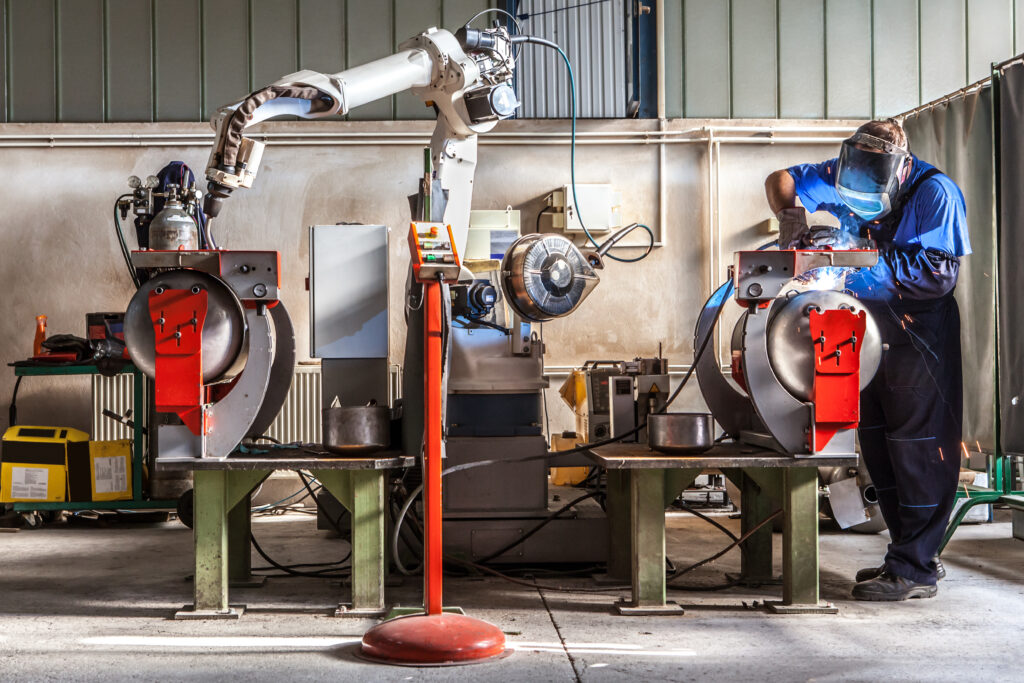

The welding profession is facing a global workforce decline: aging demographics, fewer young recruits, and high attrition. In the U.S., about 330,000 new welders are needed between now and 2028. Robotic welding helps bridge this gap:

- A single skilled operator can manage multiple welding cells rather than welding by hand.

- Cobots (collaborative robots) are intuitive to program and safe to operate alongside humans, democratizing automation.

Adoption of robotics becomes not just beneficial, but essential to maintain competitiveness.

6. Flexibility and integration

Modern robotic welding is highly versatile:

- Systems support multiple welding processes (MIG, TIG, spot, pipe welding) and can handle diverse angles and materials with programmed precision.

- Robots can integrate with material-handling systems, vision-based setups, and part feeders to create fully automated welding cells.

- Collaborative robots allow easy re-tasking, suitable for small-batch production or frequent changeovers.

This adaptability enables tailored automation solutions across industrial environments.

7. Digitalization and smart capabilities

Robotic welding systems are integral to digitalized, Industry 4.0 environments:

- Active visual sensing such as seam tracking and weld pool monitoring enables real-time adjustments, ensuring weld precision.

- Welding cameras using HDR sensors and machine learning can detect defects in-process, optimizing quality and reducing downtime.

- Robots generate valuable data such as trend logs, efficiency metrics, error reports, feeding into analytics systems that drive continuous improvement and digital transformation.

These technologies enhance traceability and support methodical optimization of welding processes.

AR‐enhanced robotic welding solution

Seabery Robotic Welding Simulator offers an innovative solution via Soldamatic for Robotics, an augmented reality‑based welding simulator designed specifically for robot welding training.

It enables operators to program and test welding trajectories virtually before implementation on real robots (ABB, Fanuc, Kuka, Comau, UR). Powered by HyperReal‑SIM®, it delivers realistic training experiences, boosting productivity by letting learners practice welding safely and repeatedly.

By merging AR, simulation, and robotics training, Seabery’s solution addresses current industry needs: improving skill development, reducing risk, and accelerating digitalization in welding.

The future of robotic welding

Robotic welding stands at the forefront of industrial modernization; delivering unmatched consistency, efficiency, safety, and flexibility. As digitalization and workforce shifts accelerate, these systems are no longer optional but essential.

Seabery takes this evolution further by offering an AR‑enhanced training simulator that equips welders with hands‑on robotic programming skills in a safe, efficient, and engaging environment.

In adopting sophisticated automation paired with immersive training, manufacturers can forge a sustainable and digitally proficient welding workforce: ready for the future of industrial production.