Dangerous fumes, fires or explosions, welding exposes everyone to similar health and safety risks and hazards. We can avoid accidents and injuries in the workshop if we follow the best welding safety practices and we use the appropriate safety equipment.

Here are 10 tips for improving your welding safety:

1.- Identify the hazards and the limits of your welding operation

Depending on the welding operation we are going to perform, we will need to check different issues according to the distinct hazards, but in general local ventilation, using the appropriate equipment in the best possible conditions and working with less hazardous materials are three of the best advices to start welding. Eventually, we will need to monitor constantly the air in the work area and check we don’t surpass the advisable limits.

2.- Read the owner’s manual and ask for training

Manufacturer’s recommendations are always the best safety guidelines, so we should read the welder’s operating manual to run the machine safely and also to maximise its performance.

Besides, all welders should be trained in safe use of equipment, work practices, and emergency procedures.

3.- Use protection

Safe welders protect themselves from all the potentially harmful effects of arc welding, always wearing the proper gear -fire-resistant personal protective clothing such as denim pants and a welding jacket -, including helmets, goggles, and other eye protection containing special filter lenses or plates.

Don’t forget about the shoes! High-top leather shoes or boots provide the best foot protection, do not use tennis or clothing shoes.

4.- Clean breathing

Fumes and smoke emitted during welding are one of the main health hazards. Use an exhaust hood to remove fumes from the area and ensure enough clean breathing air is available. Some materials specifically require respirators when welding.

5.- Don’t watch the light.

Eyes are the most sensitive part of our body when it comes to welding performance and ‘arc flash’ is one of the most common injury. It takes just a moment of exposure to a welding arc’s rays for unprotected eyes to experience this painful condition.

Arc flash is a burn of the outer layer of the eye ball caused by the intense ultra-violet radiation generated by electric welding arcs. Pain may not appear until hours after the exposure.

This is one of the reasons why choosing the right helmet is crucial.

6.- Medical care

Depending on the type of welding, it may be necessary for you to have medical surveillance of lungs, skin, eyes, hearts, and hearing on a regular basis.

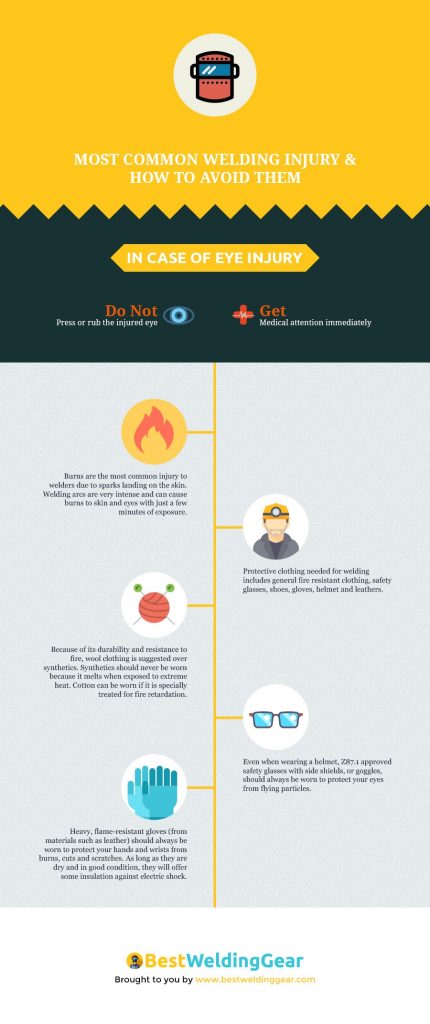

This infographic shows a summary of the main welding injury and how to avoid them:

7. Avoid repetitive stress injuries

Repetitive stress injuries or RSI are a threat for the worker’s safety in almost any job. In potentially dangerous industries like welding, their importance is even bigger. General tips for avoiding RSI are maintaining a good posture in your work or taking regular breaks from long repetitive tasks. These breaks are even more important when it comes to welding, welders need to be at a 100% when they perform a weld.

8. Take caution against electrocution

Even though small electric shocks can be common during welding, it should not become something that happens very often. The key to avoid electric shocks is to make sure the equipment is in good condition and dry. Using high quality protective equipment is key to avoid any kind of electric shock, even more when you are welding in humid places.

9. Avoid a messy workspace

When it comes to the welding industry, the importance of order in the workplace becomes even more important to avoid potential mistakes and dangers like burns or electric shock. However these dangers are not the only potential consequences, just imagine the issues that could happen if you use the wrong electrode in a weld or if your equipment setting are not right according to the WPS you should be following

10. Use non-conductive shoes or boots

Regular shoes are not made for red-hot sparks or slag, and they could even become a potential risk for you and your coworkers. When you are in the welding workshop, make sure you are wearing non-conductive boots, specifically designed for welding. This is the best way to avoid potential issues like electric shocks or burns.

Welding is a risky activity, that can be even more hazardous in the training stage. Fortunately, technology developers have created different edtech solutions to help in the training of different skills, such as welding, to make it safer and even more sustainable.